Heavy Duty Corrugated Cardboard Boxes

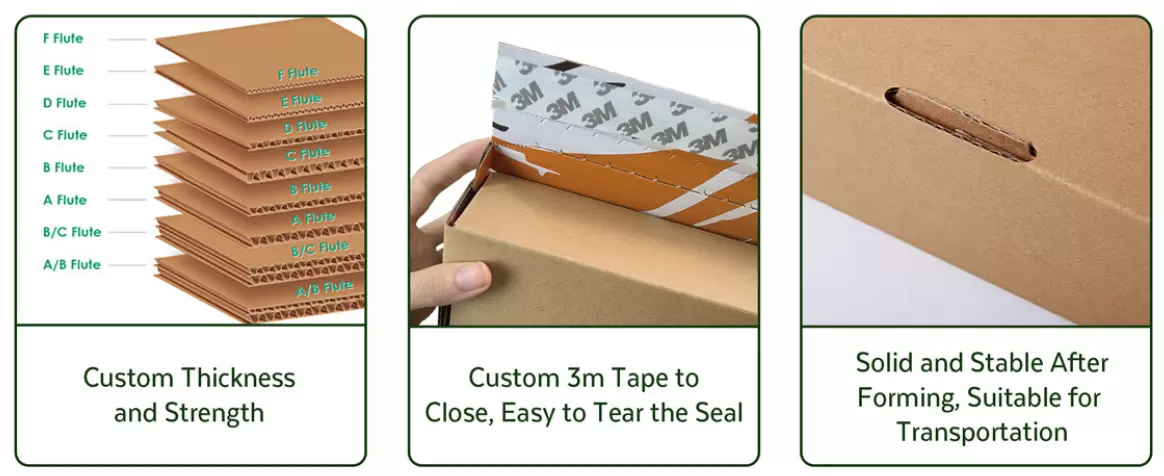

Material Option: Triple Wall/Double Wall Corrugated Board+CiS/C2S Paper

Logo Treatment: Gold Foil/Stamping, Spot UV, Embossing, Debossing etc.

Printing Handling :

Embossing, Glossy Lamination, Matt Lamination, Stamping, UV Coating, Varnishing

Size: Custom

Structural Features: Compression Resistance, Environmental Protection

Advantage: OEM& ODM

Sample time: 5-7 days

MOQ: 500

—— We are A professional Heavy Duty Corrugated Cardboard box supplier

As a professional double-wall corrugated box supplier, we always take "high strength, low cost, and sustainability" as our core concept, and provide global customers with one-stop solutions from design to mass production through material research and development, structural optimization and intelligent manufacturing technology. Whether it is precision instruments for cross-border transportation or heavy equipment on the construction site, our heavy-duty corrugated boxes can become the "invisible guardian" in your logistics chain.

— Advantages and Features of Heavy-duty Corrugated Boxes

Heavy-duty corrugated boxes are packaging containers that can carry heavier goods. Compared with ordinary corrugated boxes, they have obvious advantages in strength and durability. The following are their specific advantages and characteristics:

High strength and high load-bearing capacity

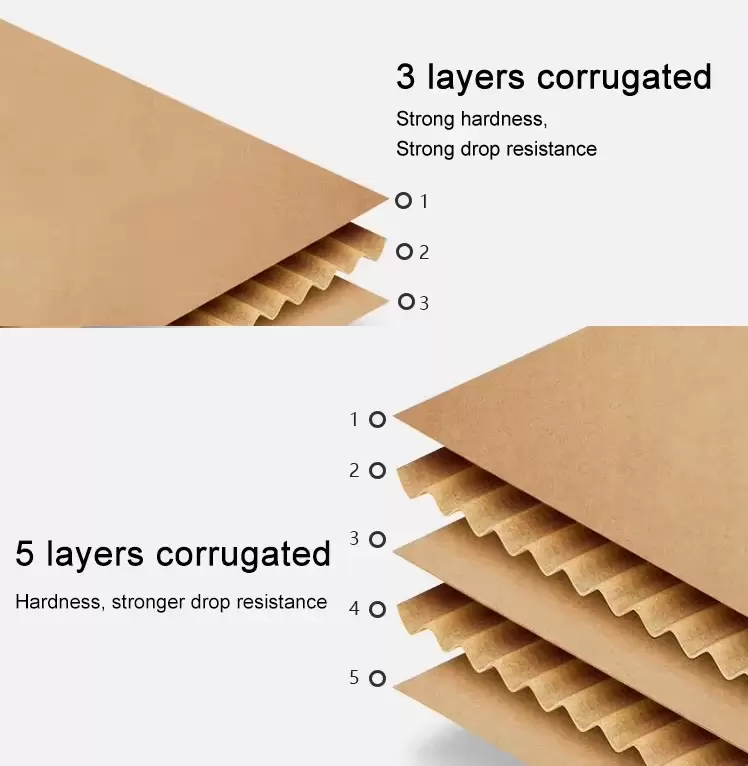

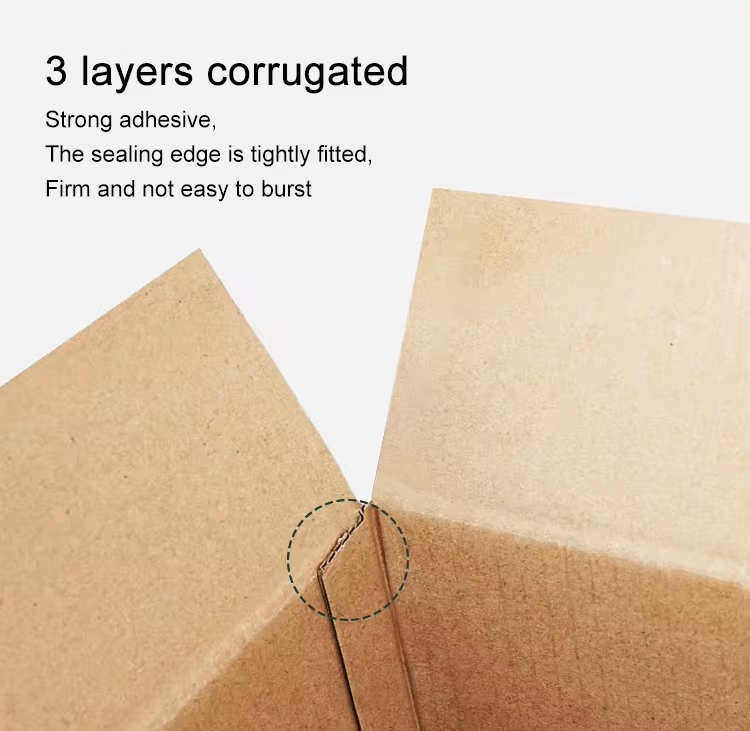

Multi-layer structure design: Heavy-duty corrugated boxes are usually made of multi-layer corrugated cardboard, generally with 5 layers, 7 layers or even more layers. By increasing the number and thickness of cardboard layers, the overall strength and rigidity of the box are greatly improved, enabling it to withstand greater weight and pressure.

High-quality raw materials: During the production process, high-strength base paper will be selected. These base papers have high physical properties such as ring compression strength, bursting strength and tensile strength, providing solid internal support for the box, which can ensure that the box is not easy to deform or break when loading heavy goods.

Good buffering performance

Corrugated structure buffering: The corrugated layer of heavy-duty corrugated boxes plays a key buffering role. The corrugated wave structure can absorb and disperse energy by deformation when subjected to external force impact, effectively reducing the impact force on the goods and protecting the contents from damage.

Can be used with cushioning materials: In addition to its own cushioning performance, it can also be used in combination with other cushioning materials (such as foam plastics, air cushion films, etc.) to further enhance the cushioning effect. It is suitable for packaging fragile and easily damaged heavy items.

Good moisture-proof performance

Moisture-proof coating treatment: In order to adapt to different transportation and storage environments, the surface of heavy-duty corrugated boxes is usually treated with moisture-proof coatings, such as waterproof paint, moisture-proof wax, etc. These coatings can form a protective film on the surface of the carton, effectively preventing the intrusion of moisture and preventing the carton from losing strength due to moisture.

Moisture-proof base paper: Some heavy-duty corrugated boxes will use base paper with moisture-proof properties to improve the moisture-proof ability of the carton from the raw material level, and even in a humid environment, it can maintain good stability and strength.

Environmental protection and recyclability

Recyclable materials: Heavy-duty corrugated boxes are mainly made of paper materials, and paper is a recyclable and environmentally friendly material that meets the requirements of modern society for environmental protection. Used cartons can be recycled and reprocessed to make new paper products to reduce pollution to the environment.

Degradability: Compared with some plastic packaging materials, heavy-duty corrugated boxes are easier to degrade in the natural environment. They will not remain for a long time like plastics, causing pollution to soil and water sources, etc., and have good eco-friendliness.

Convenience of processing and use

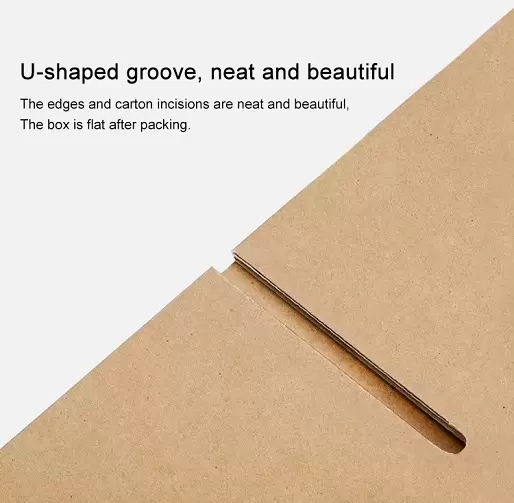

Easy to process and shape:

The production process of heavy-duty corrugated boxes is relatively mature, and the processing equipment and technology can achieve fast and efficient production. Various specifications of cartons can be easily customized according to different cargo sizes and shapes to meet diverse packaging needs.

Easy to carry and load and unload:

Compared with heavy packaging such as wooden boxes, heavy-duty corrugated boxes are lighter in weight and easier to carry and load and unload manually. At the same time, various structures that are easy to carry can be designed on the cartons, such as handles, side ears, etc., to improve the convenience and efficiency of handling.

Marking and printing:

The surface of heavy-duty corrugated boxes is flat, which is convenient for marking and printing. Product information, warning signs, logistics signs and other contents can be clearly printed on the cartons to facilitate the identification, management and transportation of goods.

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi