Custom Strong Corrugated Packaging Boxes

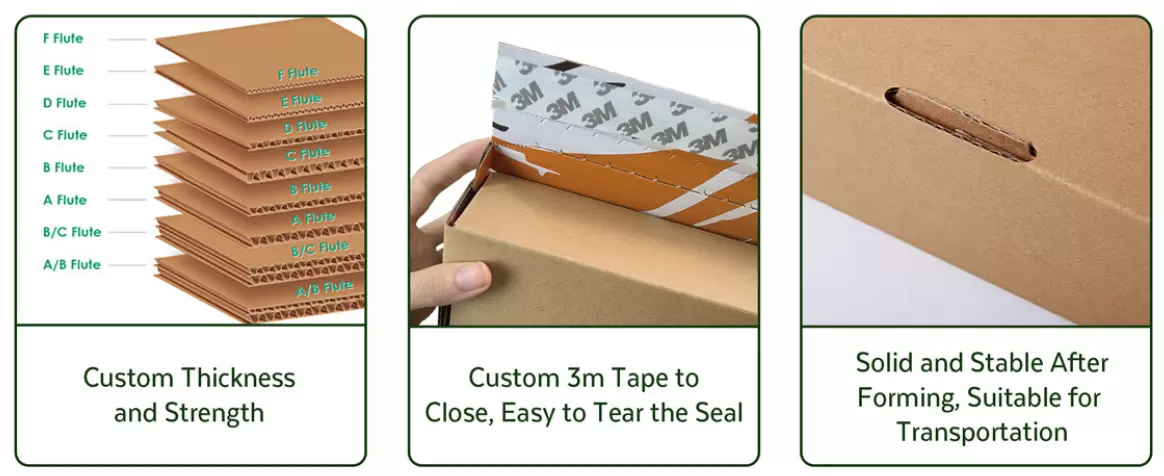

Material Option: Triple Wall/Double Wall Corrugated Board+CiS/C2S Paper

Logo Treatment: Gold Foil/Stamping, Spot UV, Embossing, Debossing etc.

Printing Handling :

Embossing, Glossy Lamination, Matt Lamination, Stamping, UV Coating, Varnishing

Feature: Strong Bearing Capacity, Recyclable, Eco-Friendly

Size: Custom

Sample time: 5-7 days

MOQ: 500

With the explosive growth in e-commerce large-scale transportation, new energy equipment (such as lithium batteries), and engineering machinery exports, the demand for heavy-duty packaging is increasing. Heavy-duty corrugated boxes can not only replace wooden boxes and iron boxes to complete the "last mile" delivery, but also empower the digitalization of the supply chain through intelligent design (traceable labels).

Selection of Strong Corrugated Cardboard Packaging Boxes Size

The selection and design of the size of heavy-duty corrugated boxes requires comprehensive consideration of many factors such as the characteristics of the goods, transportation, and warehousing requirements, and the following are the relevant points:

Cargo size:

Accurately measure the length, width, and height of the goods, including any protruding parts or irregular shapes that may exist. Generally speaking, the inner diameter of the carton should be 2-5 cm larger than the maximum size of the goods to ensure that the goods can be easily placed and the carton will not be over-extruded during transportation due to small space. For irregularly shaped goods, the carton size should be determined based on the longest, widest, and highest points of the goods.

Quantity of goods:

If you need to pack multiple pieces of goods in one carton, calculate the carton size based on the arrangement and quantity of the goods. For example, if the goods are cubes, and you plan to place 3 pieces in each row in the carton, with a total of 4 rows and 2 layers, you need to determine the length, width, and height of the carton based on the size of the individual goods and the reserved gap.

Buffering material space:

If foam board, air cushion and other buffering materials are required, the thickness of the buffering materials should be reserved in the carton size. Generally, the buffering materials should reserve 1-3cm thickness space on both sides of the goods, depending on the fragility of the goods and the type of buffering materials.

Transportation and storage space:

Consider the size restrictions of transportation, such as the width, height, and length of the truck compartment, the internal dimensions of the container, etc., to ensure that the cartons can be loaded reasonably, without wasting transportation space, and convenient loading and unloading. At the same time, the size of the carton should also be determined in combination with factors such as the size of the storage space and the stacking method, such as the height and width of the warehouse shelves, to facilitate stacking and storage. In general, the height of the carton should not exceed the height limit of the warehouse shelf, and the width and length should match the shelf size to facilitate neat placement.

— Heavy Duty Corrugated Boxes Design Points

Structural design

Flute type selection: Strong corrugated cartons often use a combination of B flute, C flute, and BC flute. B flute has a shorter flute height, more flutes, better flat compressive strength and printability; C flute has a moderate flute height, more balanced cushioning, and compressive performance; BC flute combination has the advantages of both, and can provide better strength and cushioning effect.

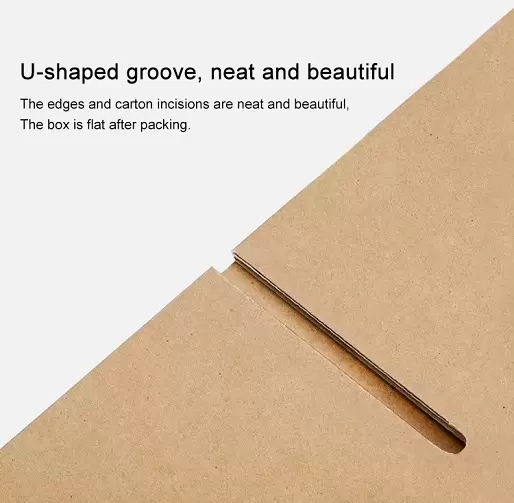

Box design: Common box types include 0201 (slotted carton), 0301 (nested carton), etc. 0201 carton is widely used, easy to open and close, and suitable for most commodities; 0301 carton has strong anti-extrusion ability and is suitable for commodities with high requirements for top pressure resistance. Some commodities with special shapes or special requirements can also be designed into special-shaped cartons, such as triangles, circles, etc., but the structure must be stable.

Material selection

Base paper quality: Use high-strength base paper, such as imported kraft paper or high-quality domestic kraft paper, which has high indicators such as ring compression strength, bursting strength, and tensile strength, which can provide good basic strength for the carton. The quantitative is generally between 150~300g/m2, determined according to the weight of the commodity and the size of the carton.

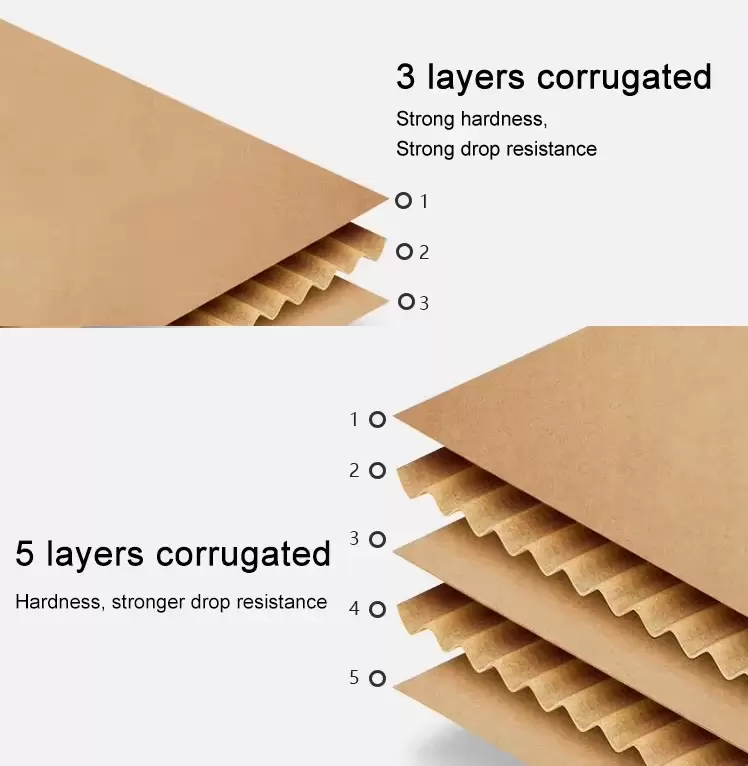

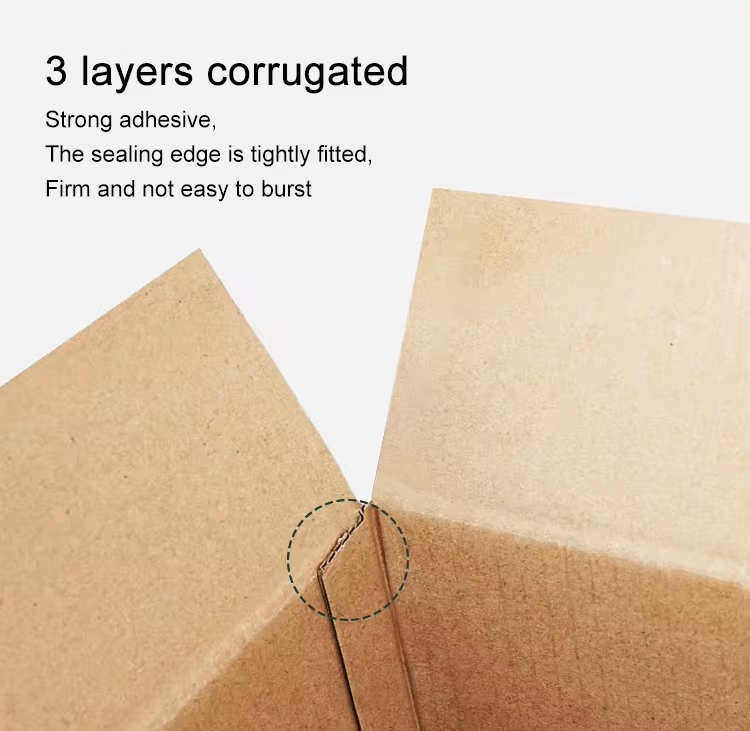

Layer selection: The number of layers of corrugated cardboard is determined by the weight of the goods and the requirements for the strength of the carton. Generally, there are 5 layers, 7 layers, or even 9 layers. 5-layer corrugated cardboard is suitable for heavy goods of normal weight, while 7 or 9 layers are used for overweight, oversized or extremely high-strength goods.

Printing and labeling

Content design: The carton should be printed with the product name, specifications, quantity, weight, production date, shelf life, handling and storage precautions, warning signs and other information for easy identification and management.

Printing technology: Use high-quality printing technology such as offset printing and flexographic printing to ensure that the printed pattern and text are clear, firm, and colorful to avoid fading or blurring during transportation and storage.

Contact us today to unlock the endless possibilities of customizing strong cardboard packing boxes.

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi