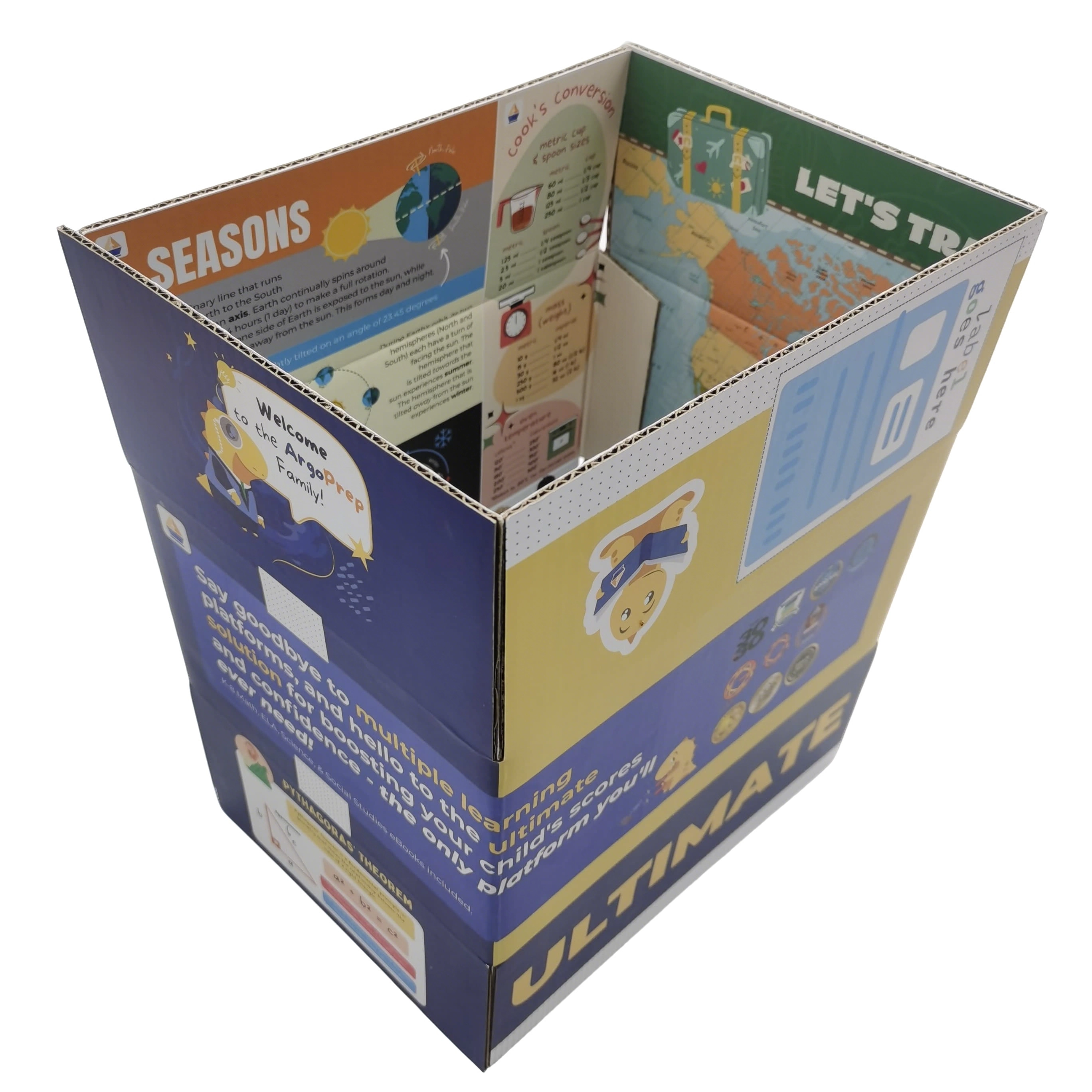

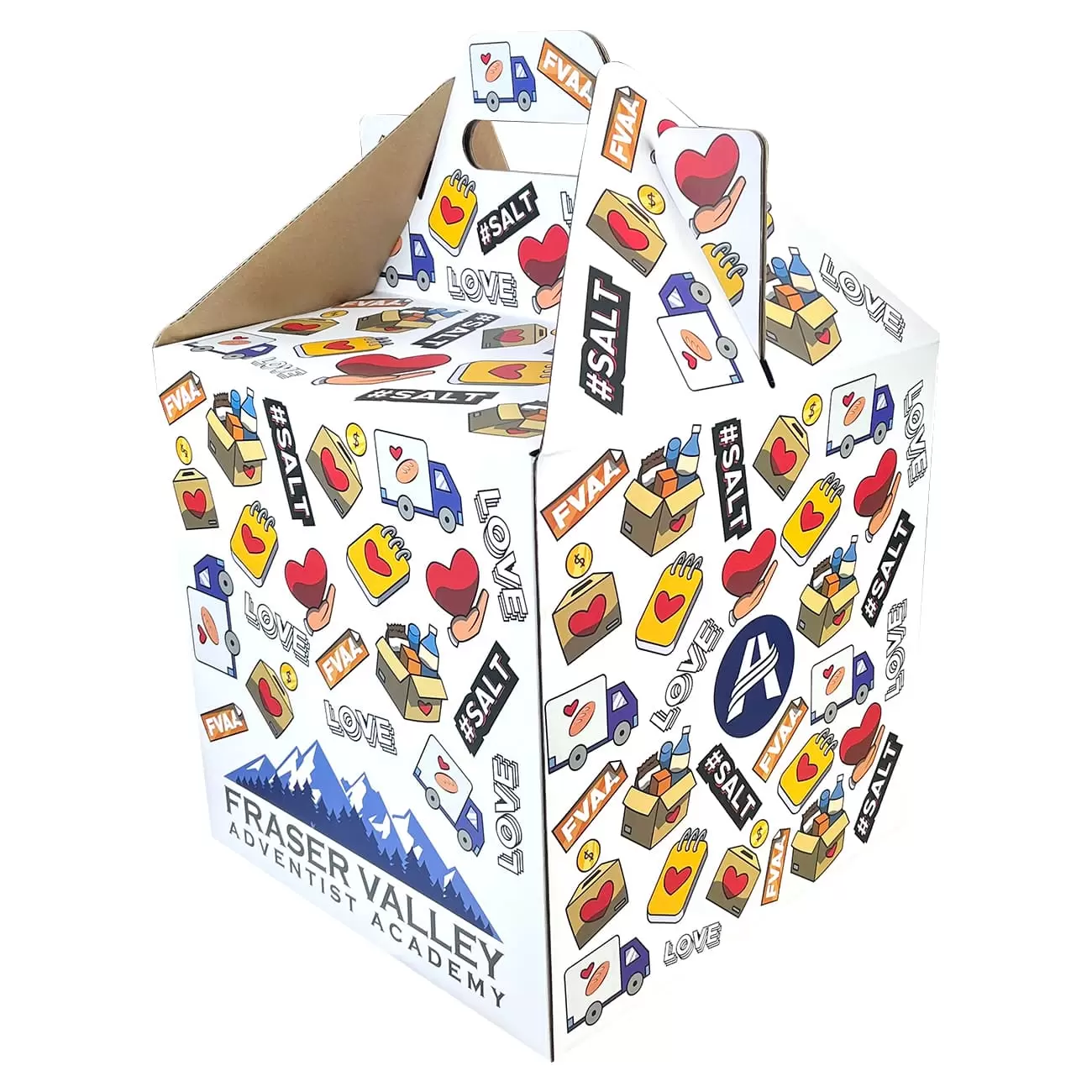

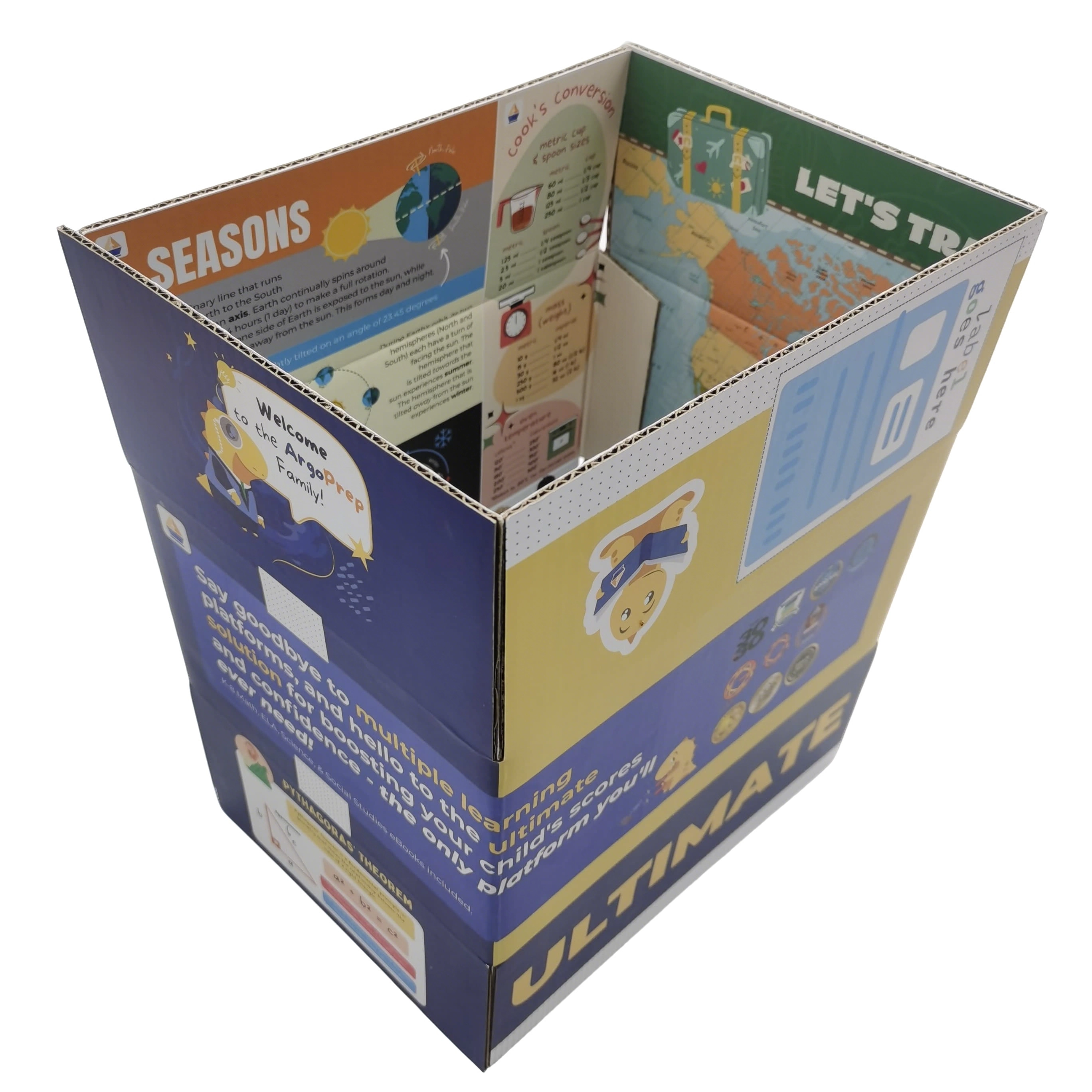

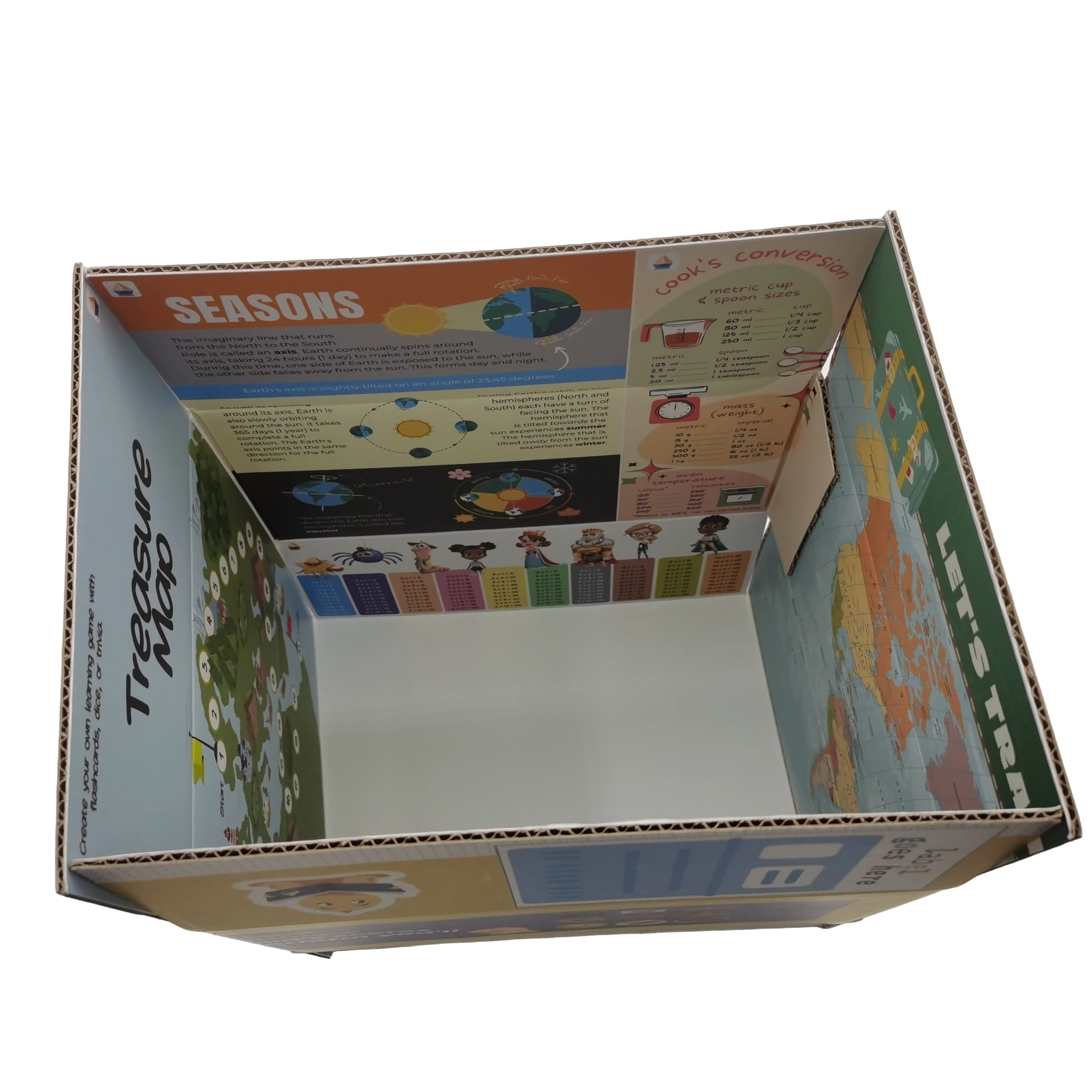

Double Wall Corrugated Cardboard Cartons

Material Option: Double Wall Corrugated Board+CiS/C2S Paper

Logo Treatment: Gold Foil/Stamping, Spot UV, Embossing, Debossing etc.

Printing Handling :

Embossing, Glossy Lamination, Matt Lamination, Stamping, UV Coating, Varnishing

Size: Custom

Feature: Zipper opening, Double Wall Corrugated, Recyclable, Eco-Friendly

Advantage: OEM& ODM

Sample time: 5-7 days

MOQ: 500

We Are a Professional Supplier of Double Wall Corrugated Cardboard Cartons

As a professional supplier of double-wall corrugated boxes, our core advantages lie in high-precision production capacity, diversified structural design and large-scale supply chain management.

1. Technical Adaptation

Material and process optimization

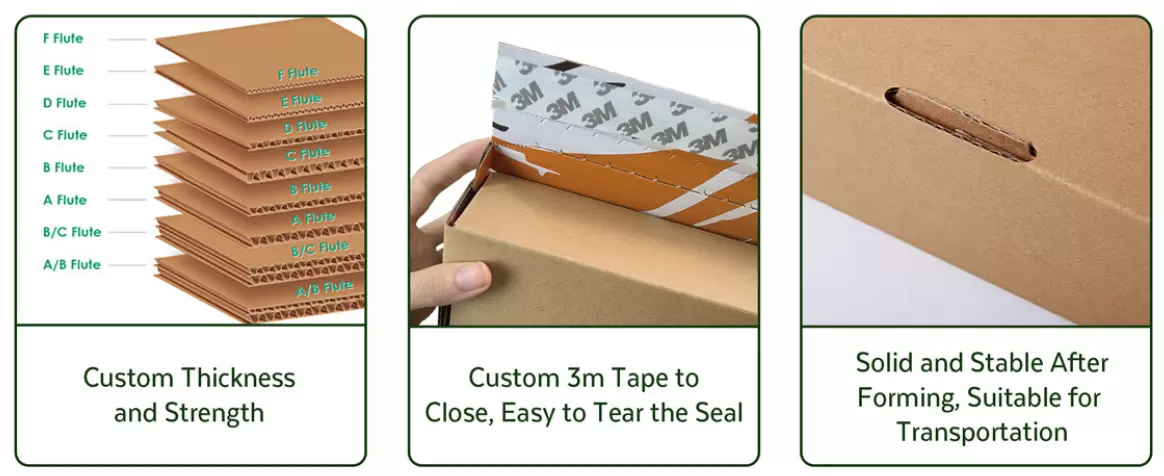

Flute type combination: Double-wall corrugated (such as AB flute and BC flute combination) can take into account both cushioning and pressure resistance, and is suitable for high-value-added goods such as electronic products and precision instruments.

Special Treatment:

Moisture-proof coating (such as polyethylene coating) improves the applicability of cold chain transportation;

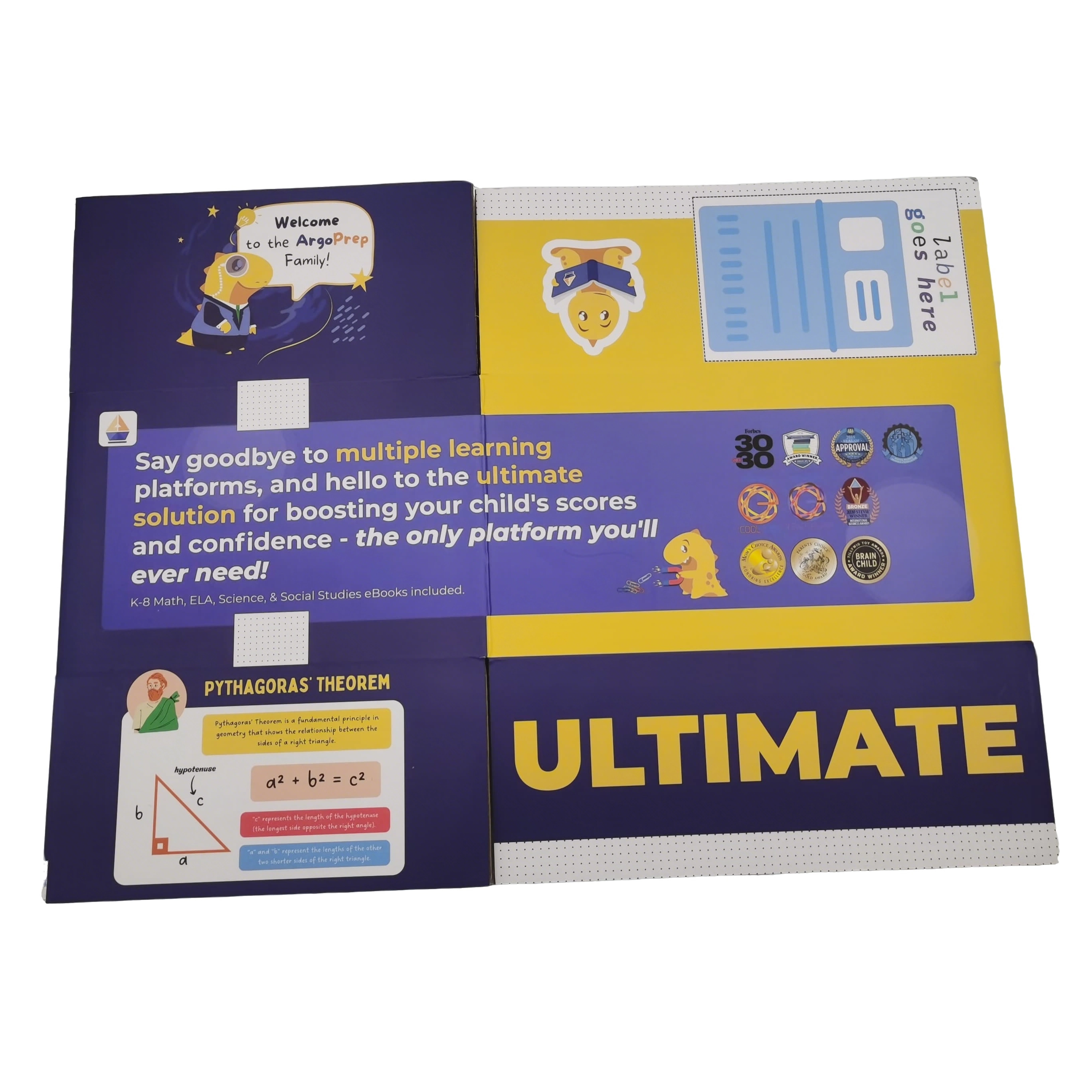

Pre-printing technology enables high-resolution brand pattern printing.

Intelligent Design

Embed temperature and humidity sensing labels or tear indicator strips to enhance the added value of packaging functions.

Modular structural design supports rapid size adjustment to adapt to different customer needs.

2. Application industry

3C electronics: Provide customized solutions with built-in cushioning pads + anti-static resistor barriers to meet anti-static needs.

Fresh cold chain: Develop a combination of air permeable holes + EPS insulation layer to extend the freshness period.

Cross-border e-commerce: Design lightweight cartons (≤5 layers) to reduce international logistics freight costs.

We provide free proofing services to shorten customer decision-making cycles.

3. Cost and supply chain collaboration

Optimization of raw material procurement

We cooperate with paper mills to use recycled pulp to reduce raw material costs by 15%-20%, while complying with environmental protection trends.

We purchase corrugated paper in bulk and use economies of scale to reduce the purchase price.

Improved production process efficiency

We introduce digital printing equipment to reduce plate making costs and support small batch customized orders.

We implement the JIT production model, dynamically adjust production capacity according to customer orders, and reduce the risk of inventory backlogs.

Double-sided rinting

— Why Choose Customized Double Wall Corrugated Cardboard boxes?

Precisely match the needs

According to product characteristics (such as size, weight, and fragility) and transportation scenarios (such as long-distance shipping and short-distance delivery), tailor-made box structures, materials, and protection solutions are used to ensure "zero gap" adaptation between packaging and goods.

Cost and efficiency double optimization

Through lightweight design and modular size, material waste can be reduced and storage and transportation space utilization improved.

Recyclable or recyclable environmental protection characteristics, in line with the trend of green logistics, reduce long-term costs.

Double empowerment of brand and safety

Printing brand logos, product information, and transportation warnings to enhance brand awareness and compliance.

Scientific buffer structure and moisture-proof and pressure-resistant treatment significantly reduce cargo damage rate and protect the value of goods.

We look forward to working with you to transform the performance advantages of double-wall corrugated boxes into market competitiveness! If you need further refinement of the plan, please feel free to communicate with us!

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi