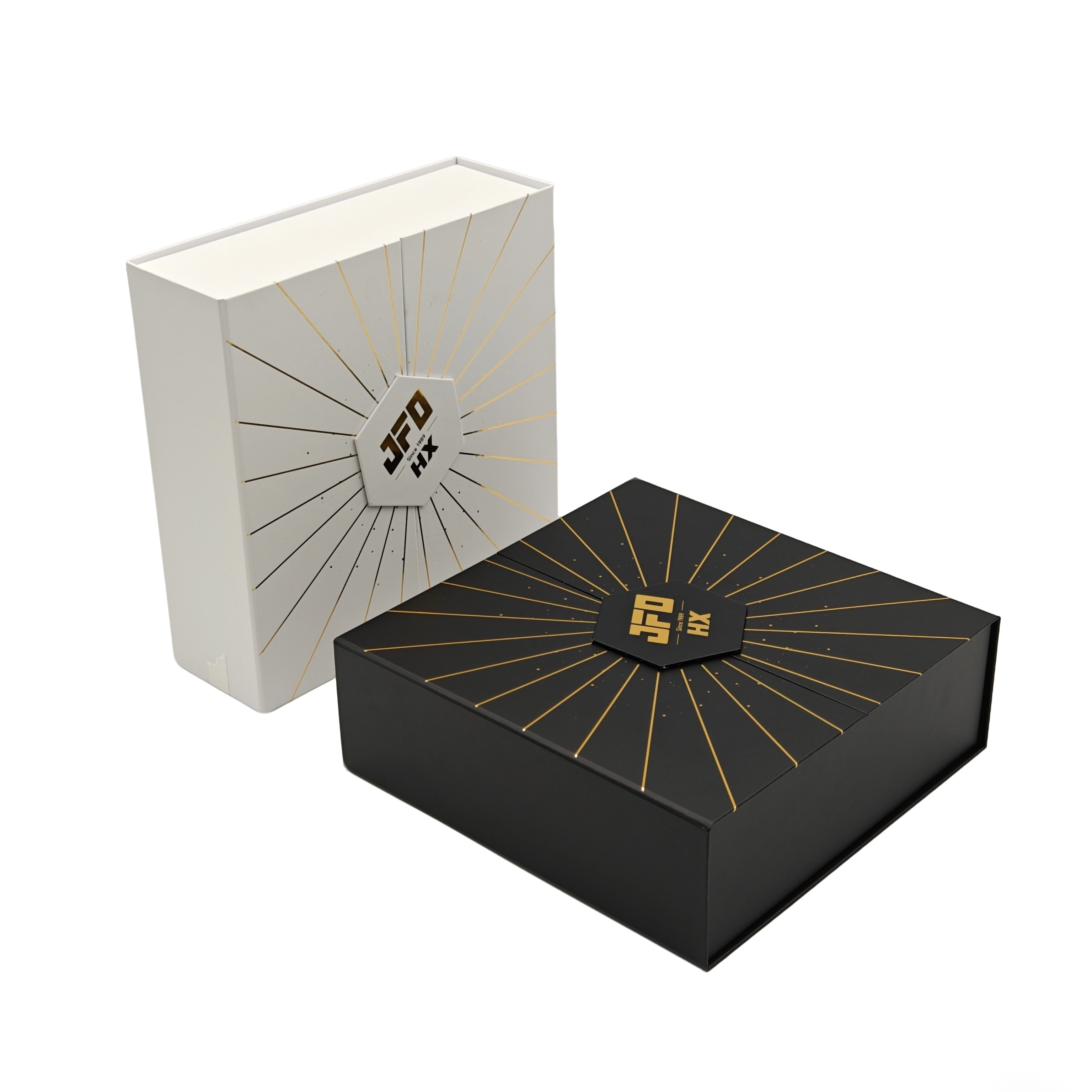

Custom Box with Magnetic Closure

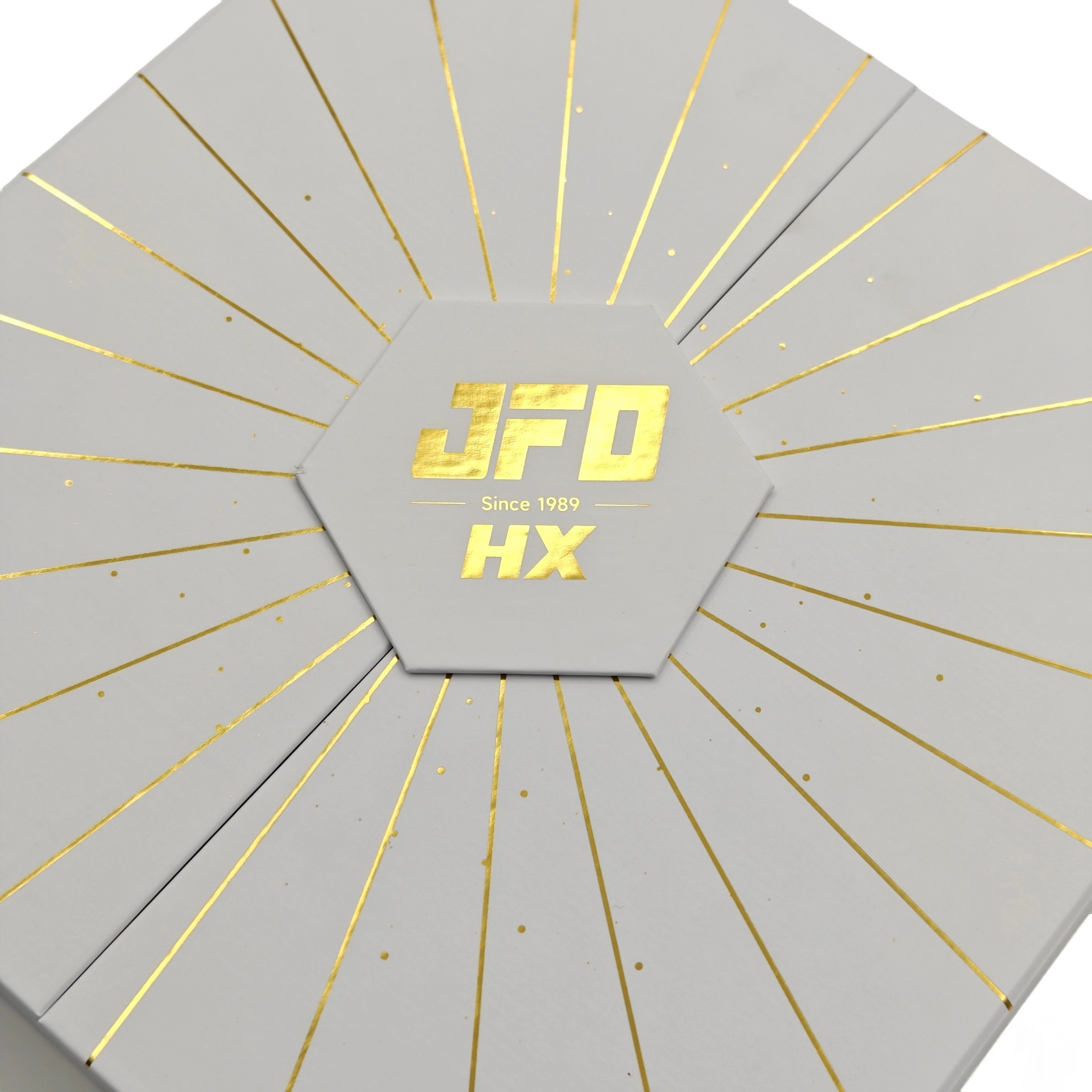

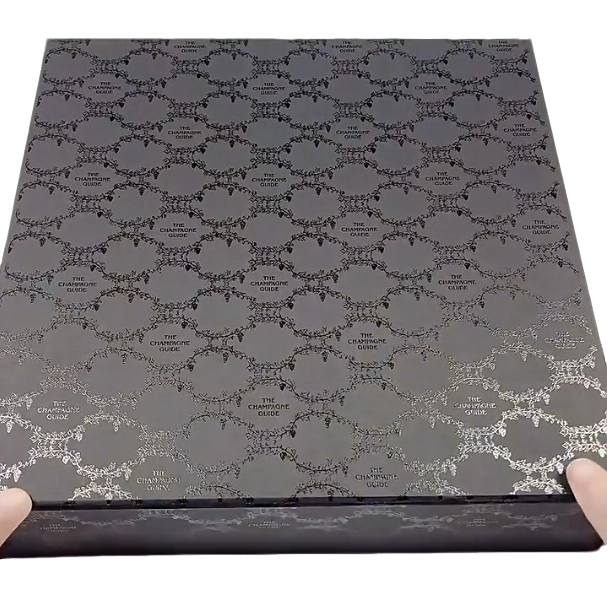

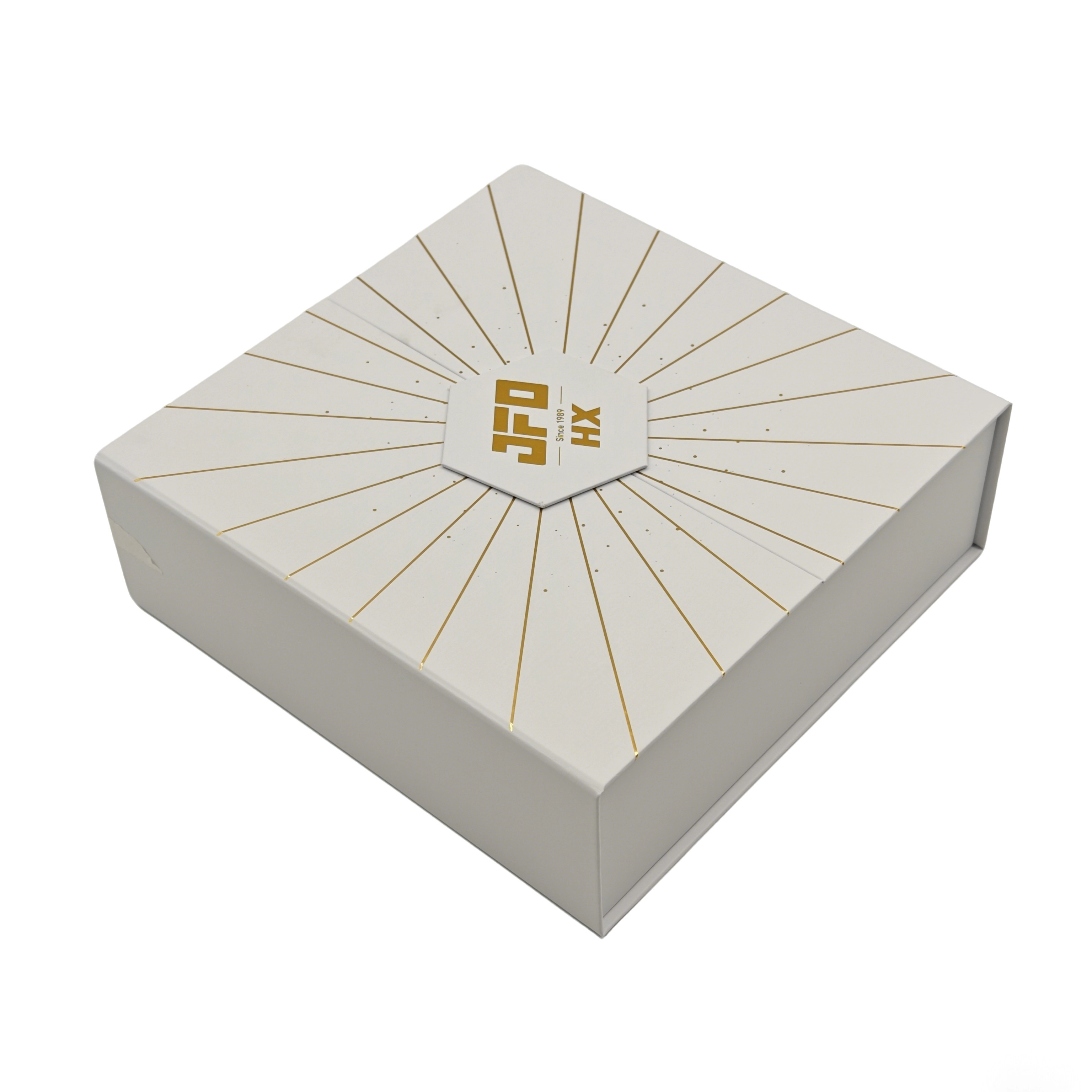

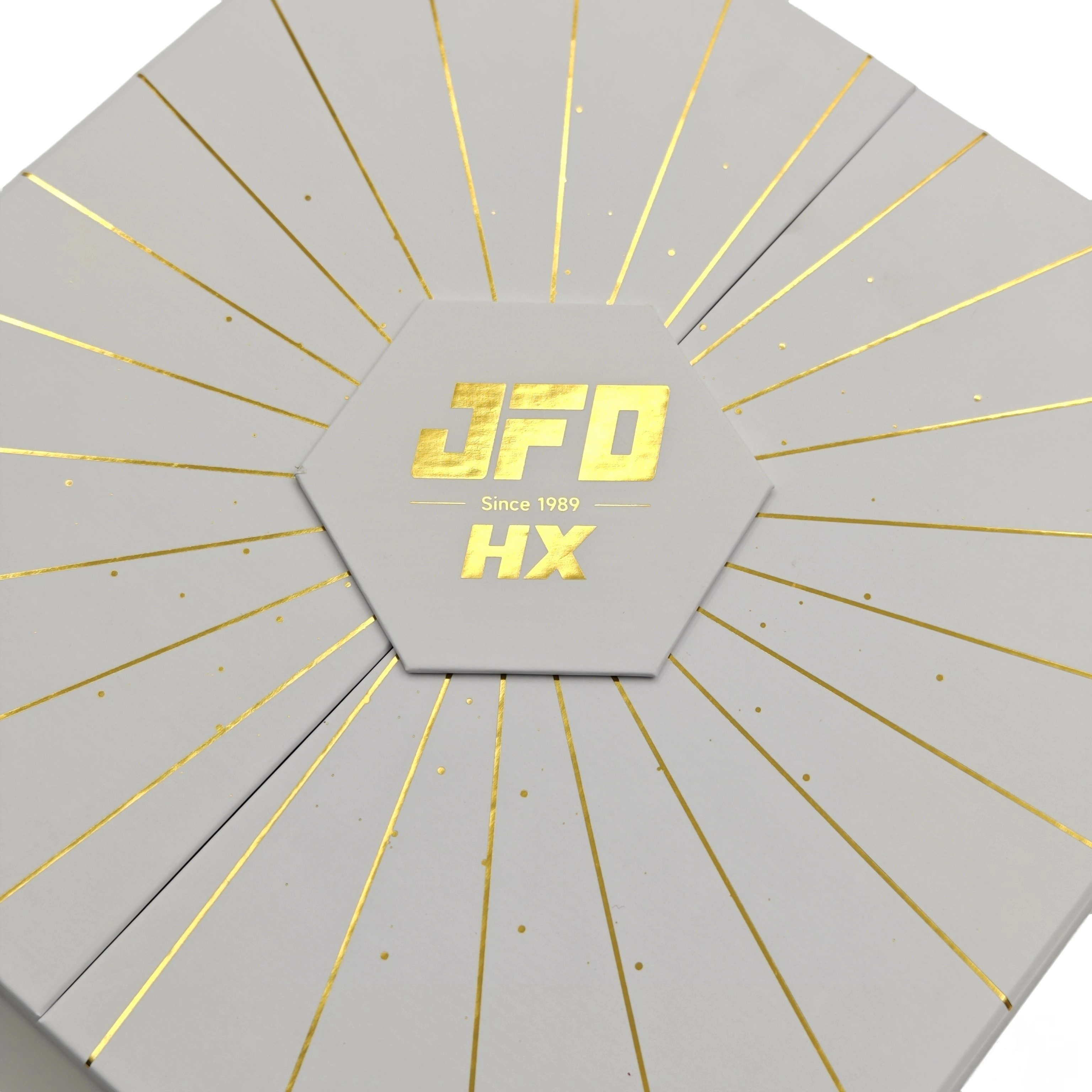

Logo Treatment: Gold Foil/Stamping, Spot UV, Embossing, Debossing etc.

Printing Handling: Matt Lamination, Varnishing, Stamping, Embossing, Glossy Lamination, UV Coating, VANISHING, Gold FoilCharacteristics.Intelligent magnetic control system:

16 Gauss neodymium magnets for precise positioning;

10,000 times of opening and closing test certification;

Silent damping closure technology;

Military-grade protective structure:

Double-layer thickened cardboard (3 mm+);

Patented buffer corner design;

Optional shockproof floating inner tray;

Shape and Size: Custom

MOQ: 500

Sample time: 5-7 days

— Features of Custom Box with Magnetic Closure

Convenience

The magnetic closure makes the box extremely convenient to open and close. There is no need for complicated zippers, buckles, or laces. The box can be closed and opened with a light suction and pull. It can be operated with one hand, saving time and energy.

Firmness

High-strength magnets or magnetic materials are used as closing devices, which make the box have a strong adsorption force when closed and can effectively maintain the integrity and safety of the box and prevent items from accidentally falling.

Aesthetics

The hidden magnetic closure is simple in design, with no obvious exposed sealing parts, making the overall appearance of the box more refined and smooth, improving the grade and beauty of the packaging, and increasing visual appeal through surface hot stamping, embossing, silk screen printing, and other processes.

Repeatability

The magnetic closure can be used repeatedly, and its sealing performance and service life will not be affected by multiple openings and closings. It is more economical and practical than some one-time sealing methods.

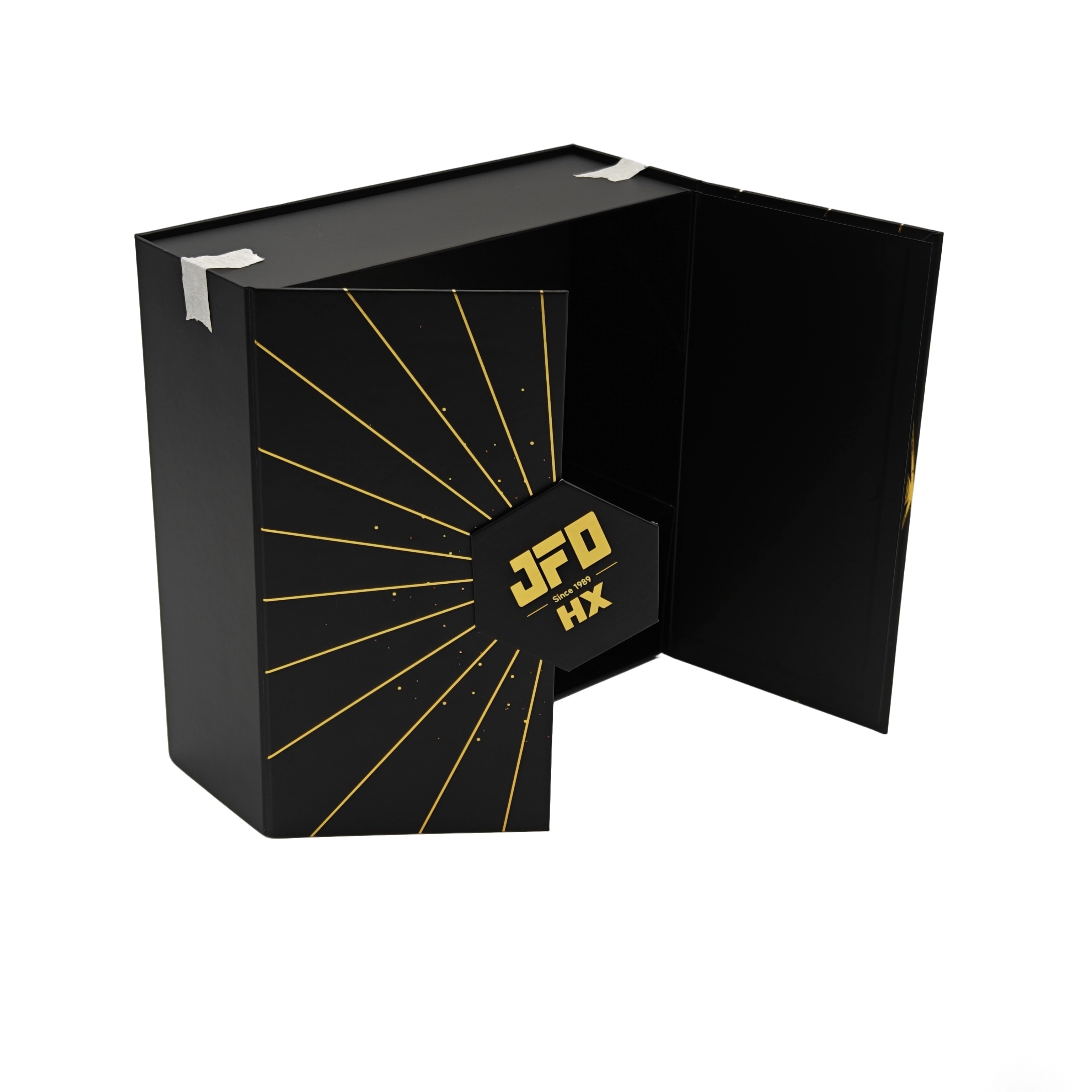

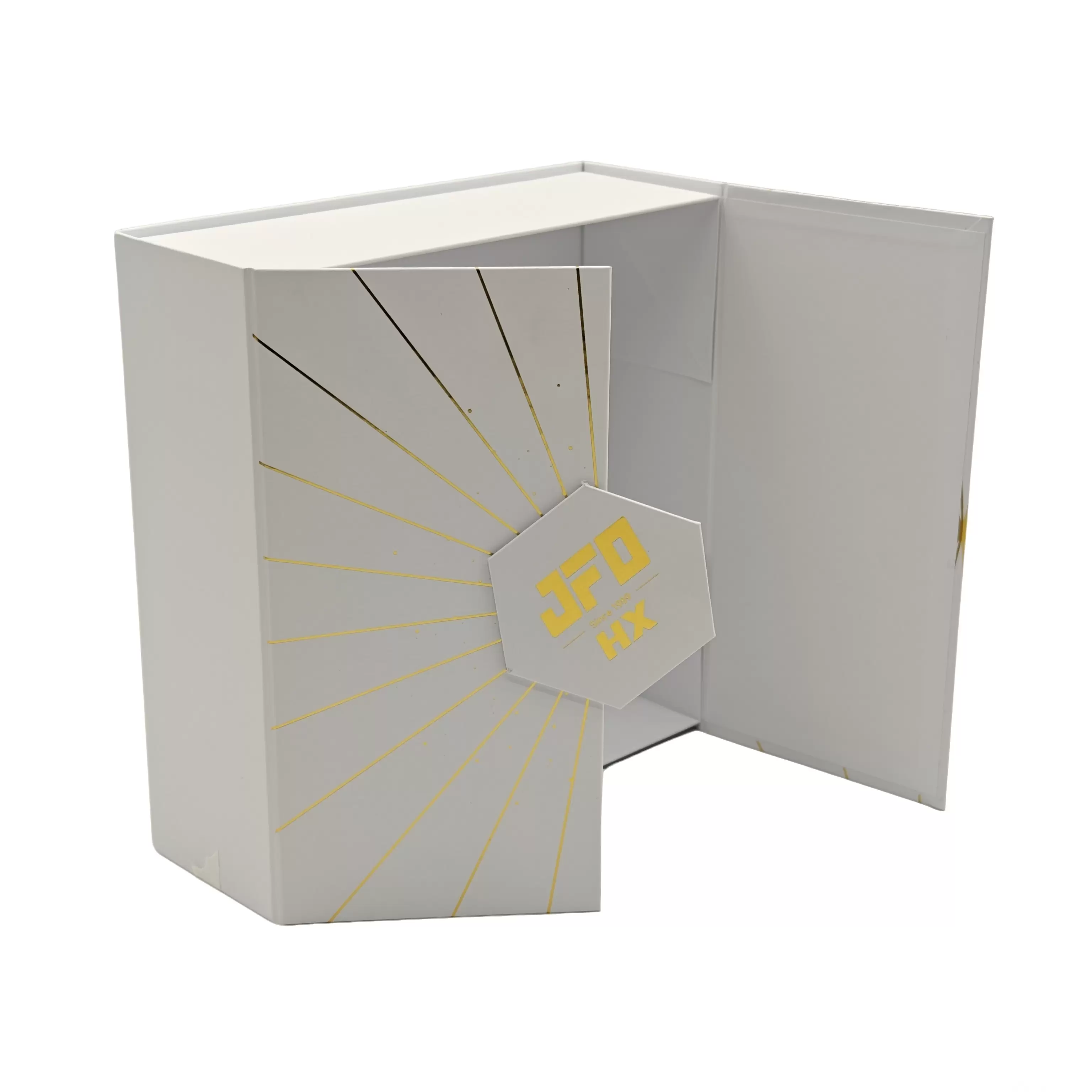

— Double-door Magnetic Gift Box: Opening a Luxurious Sense of Ritual

The custom box with magnetic closure redefines the standard of high-end packaging. With its unique biparting design and precise magnetic suction system, it creates a breathtaking sense of unboxing ritual for the brand. This innovative packaging is not only a container but also an artistic carrier of brand narrative.

Core innovation value

1. Theater-style opening experience

Beautiful and fashionable: The symmetrical opening design of the double doors, combined with the hidden magnetic suction system, creates a shocking effect like the stage curtain slowly opening. The double-door design itself has a unique visual appeal. Combined with a variety of exquisite printing, decoration techniques, and materials, it can produce a highly beautiful and fashionable packaging box to enhance the product's overall image.

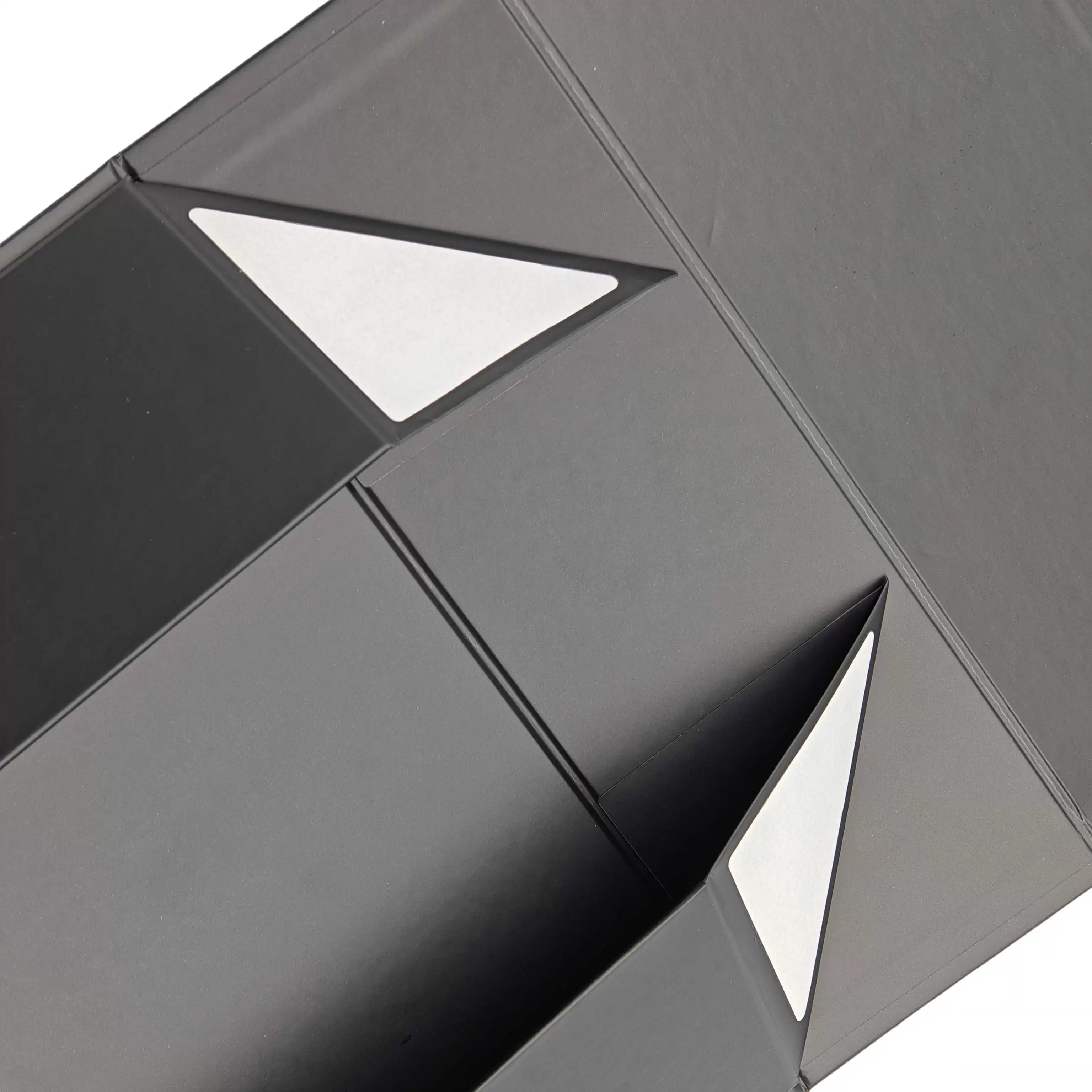

2. Military-grade protective structure

• Double-layer thickened cardboard (3 mm+)

• Patented buffer corner design

• Optional shockproof floating inner tray

Good protection performance: Through magnetic adsorption closure, the box cover and body can fit tightly, effectively preventing dust, moisture, etc. from entering the box and protecting the product from damage.

3. Intelligent magnetic control system

• 16 Gauss neodymium magnets for precise positioning

• 10,000 times of opening and closing test certification

• Silent damping closure technology

Easy to open and close: The magnetic force is relatively gentle, and users can easily open and close the lid without additional mechanical structure or complex operation, which is very convenient to use.

— Innovative Design of Double Door Magnetic Box

The following will introduce its structural characteristics, working principle, customized services, and application scenarios:

1. Structural characteristics

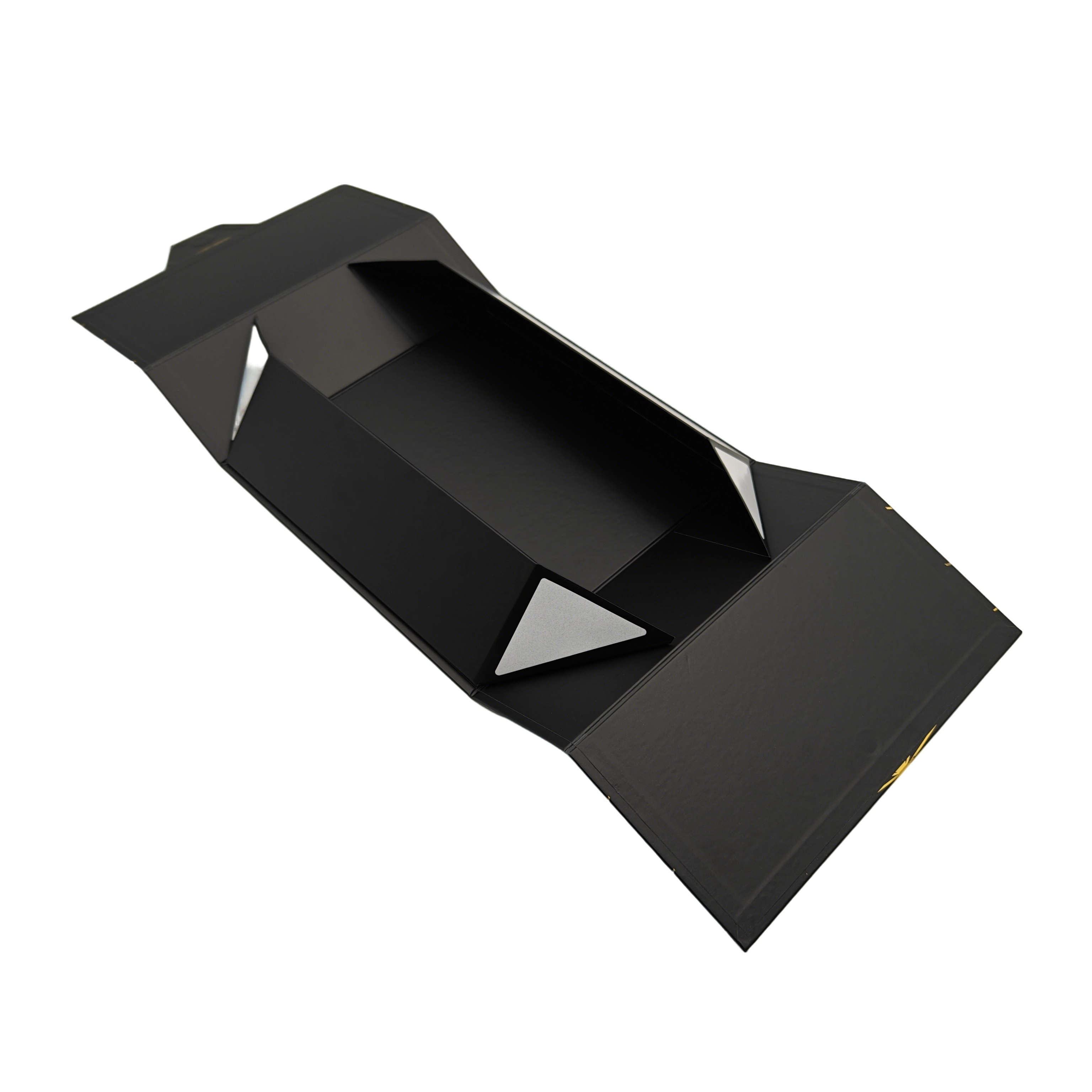

Double-door design

It is composed of a left outer box and a right outer box symmetrically, with an inner box on the inside. Compared with the traditional single-door design, the double-door box is more refined, the structure is more stable, the opening is larger when displayed, and the display effect is good.

Custom Multi-layer structure combination

Through a multi-layer structure, box-type combination, combined with three-dimensional illustrations, window design, and other visual creativity, a three-dimensional sense of space for the gift box can be created to help create a sense of opening ceremony.

2. Working Principle

Magnetic adsorption: magnets or magnetic materials are embedded in the opening and closing of the double-door magnetic box, and the mutual attraction between the magnets is used to achieve a tight closure between the box lid and the box body. When you need to open the box, you only need to overcome the magnetic force and gently pull open the box lid. When closing, it can automatically adsorb and close by magnetic force, which makes it convenient to operate.

3. Customized Service

Size Customization

According to customer needs, make hot-stamping foldable magnetic gift boxes of different sizes to meet the packaging needs of various items.

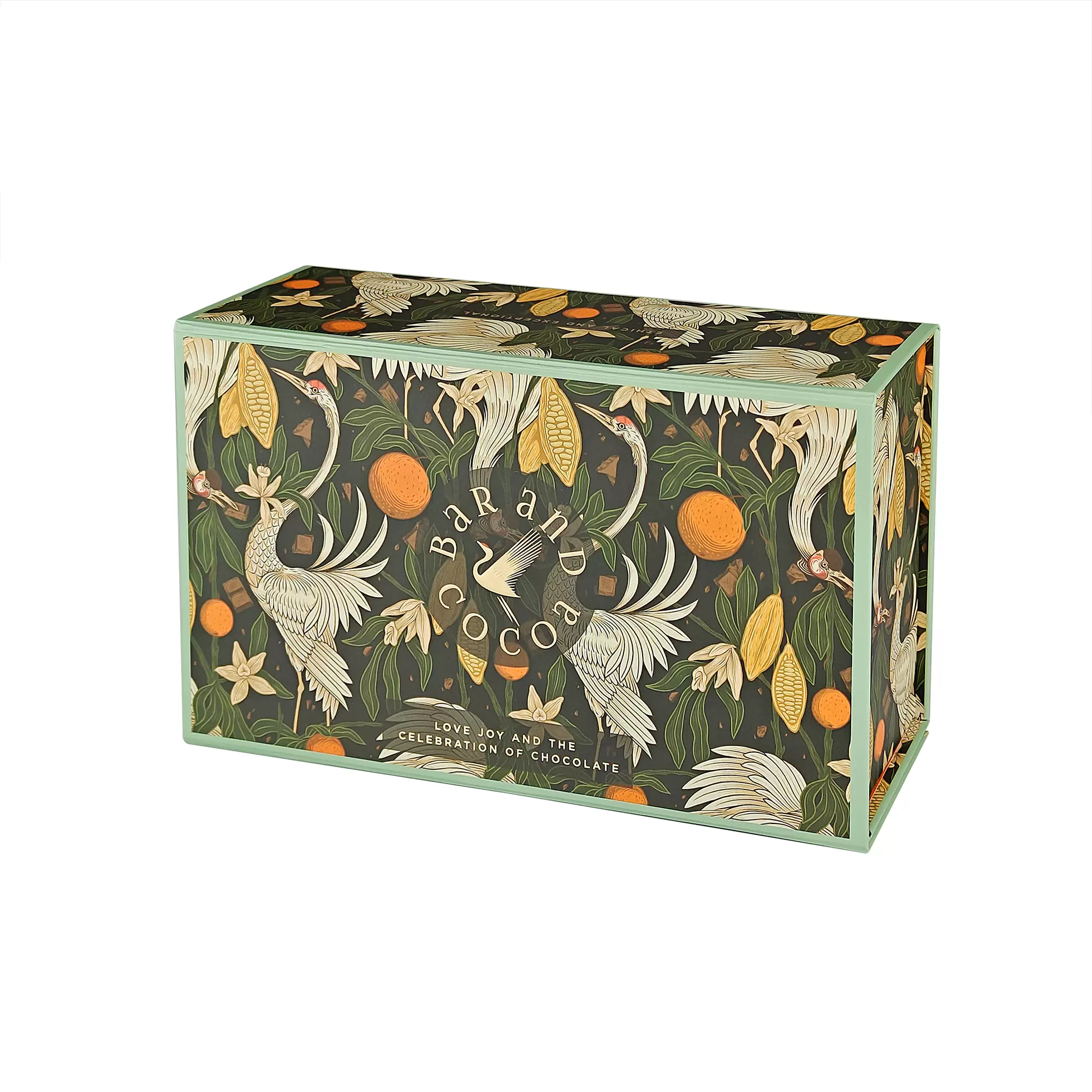

Pattern Customization

Customers can provide their design patterns, logos, etc., or professional designers can make creative designs according to customer requirements to make the gift box unique and personalized.

Color Customization

Choose different background colors and hot stamping colors to meet customer requirements for gift box color matching, so that it matches the gift or brand image.

Function customization: In addition to the basic magnetic closure function, some special functions can be added according to customer needs, such as built-in sponges, satin, and other linings to better protect and display items, or handles, ribbons, and other decorations for easy carrying and giving.

4. Application Scenarios

Business Gifts

In business activities, it can be used to package business gifts, souvenirs, promotional materials, etc., which helps to enhance the corporate image and strengthen the relationship with customers and partners.

Festival Celebrations

In festivals such as the Spring Festival, Mid-Autumn Festival, Christmas, and Valentine's Day, as well as weddings, birthdays, anniversaries, and other celebrations, gift packaging or decorative items create a strong festive atmosphere.

Food Packaging

Some high-end chocolates, tea, health products, and other foods will also be packaged in collapsible magnetic boxes, which can not only ensure the sealing and safety of the food but also attract consumers' attention during the display and sales process.

— Production Process of Custom Box with Magnetic Closure

Design Proofing

Design the appearance, structure, and printing pattern of the box according to the customer's needs and creativity, and make samples for customer confirmation.

Material Cutting

Cut the selected materials according to the designed size and shape to obtain the various components of the box.

Magnetic Component Installation

Accurately install the magnet or magnetic material in the corresponding position of the box to ensure the reliable performance of the magnetic seal.

Assembly Molding

Assemble the various components of the box by folding, pasting, etc., to form a complete box, and conduct final quality inspection and packaging.

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi