In the fast-paced consumer era, a carefully crafted handmade cardboard gift box can not only perfectly protect precious gifts but also make the unboxing process an unforgettable ritual experience. Whether it is a holiday gift, brand packaging, or a special commemoration, customized paper boxes carry the warmth and sincerity that cannot be replaced by mechanical mass production.

Why Choose Handmade?

✔ 100% tailor-made—precisely match the size and style of the gift

✔ Environmentally friendly and sustainable use of degradable materials to reduce packaging waste

✔ The controllable cost of a single box is as low as ¥3

✔ Creative freedom, from minimalism to luxurious relief, can be achieved

This Guide Will Reveal

A 6-step molding method that can be completed with household tools without professional equipment.

Five surface treatment processes that upgrade ordinary paper boxes to luxury goods.

Load-bearing calculation formula to avoid structural collapse.

Quality inspection standards and cost control secrets for commercial-grade packaging.

"Packaging is a silent salesperson. Let's start with an ordinary cardboard box and create an unforgettable gift temple.

— A complete guide to making a gift box with cardboard

(handmade DIY + professional-level craftsmanship, including size calculation, structural design, and decoration skills)

I. Materials and tool preparation

Material Recommended specifications Alternative solutions

Cardboard 1.5-2mm gray board/corrugated paper Express box transformation

Decorative paper: 120-150g art paper, Wrapping paper/kraft paper

Adhesive White latex (handmade), hot melt glue (quick shaping)

Tools Use Optional Upgrades

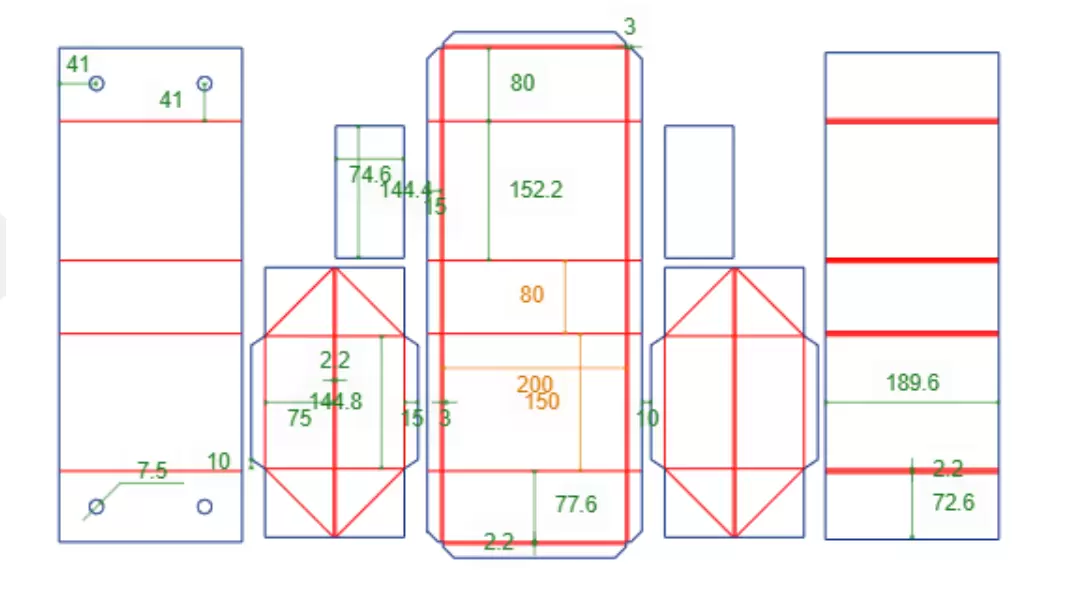

Utility knife + steel ruler, Precise cutting, Laser cutting machine (accuracy 0.1mm)

Bone pen/crease pen, Press out clear creases with a creasing machine (professional grade)

Compass + divider Draw circles/equal division marks 3D modeling software

II. Box Design and Size Calculation

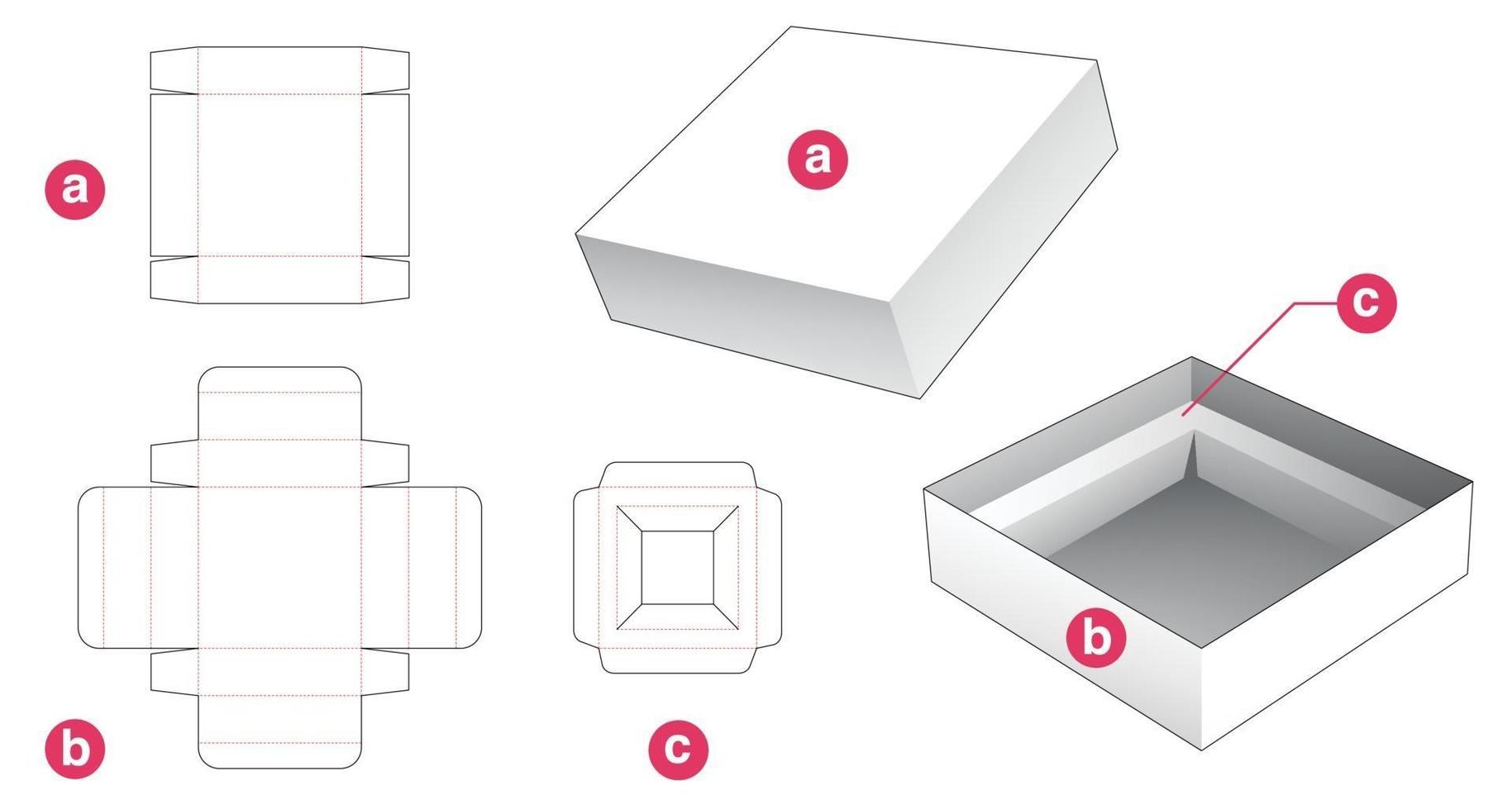

1. Basic Square Box Formula

Box bottom size = item length and width + 3 mm (elasticity)

Box height = item height + 10mm (including lining)

Cardboard cutting diagram:

+-------------------+

| (Height) | ← Side Panel

+-----+---------+-----+

| (Height)| (Length) | (Height)| ← Bottom Panel + Side Panel

+-----+---------+-----+

| (Width) | ← Adhesive Edge

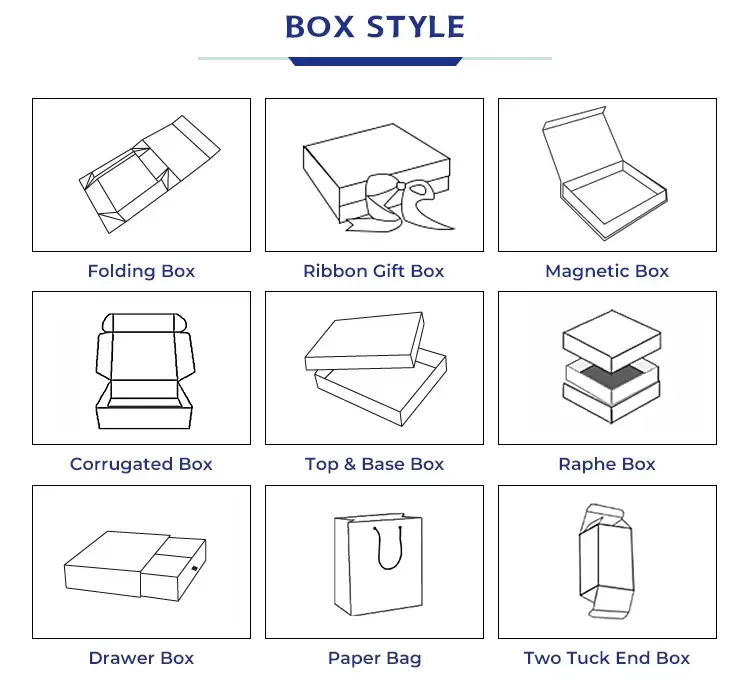

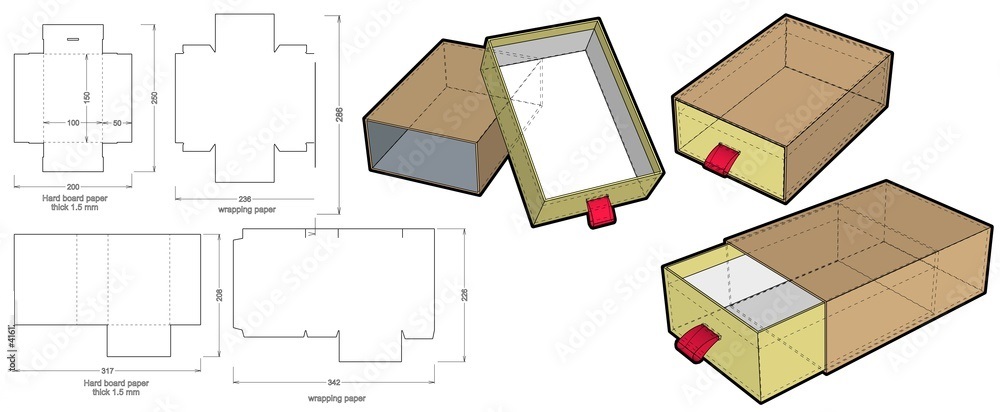

2. Advanced Drawer Box

Gap between inner and outer boxes: 1.5mm on one side (smooth sliding)

Pull-out tongue length: 1/3 of box width (20mm standard hand feel)

III. Production Steps (Taking Lid and Base Boxes as an Example)

▸ Step 1: Precise Cutting

Outline on the cardboard according to the design (it is recommended to make a 1:1 paper pattern first)

Cutting tips:

The blade is at a 30° angle to the cardboard

Each cut only 70% of the depth, and it is completed in 2-3 times

▸ Step 2: Indentation and Folding

Use a bone pen to scratch along the fold line (the strength is best when the cardboard fiber is slightly cracked)

Professional folding method:

▸ Step 3: Assemble and Shape

Glue selection:

Handmade: white latex (leave for 3 minutes after coating before gluing)

Quick shaping: hot melt glue (120°C low-temperature glue stick)

Reinforcement techniques:

Add right-angle cardboard to the corners (2 cm wide)

1mm EVA sponge lined in the lid (to improve the feel)

IV. Five Types Advanced Decoration Schemes

1. Hot Stamping Process

Tools: hot stamping pen + transfer film

Temperature: 130℃/3 seconds (need to try a sample first)

2. Hollow Window

Window size: less than 30% of the box surface

Sealing material: 0.2mm PET film (food grade)

3. Magnetic Switch

Magnet specifications: 10×2mm neodymium magnet (N35 grade)

Positioning formula

text

Magnet center distance to box edge = box height × 0.618

Texture modification

4. Embossed tools

Leather texture (using iron + silicone template)

Cloth texture (pressing with gauze + diluted white glue)

5. Smart interaction

NFC chip implantation:

Location: inside the lid

Content: link to blessing video/e-card

V. Cost Optimization Techniques

Waste utilization:

Make gift cards/tags with scraps

The load-bearing capacity of corrugated paper in the horizontal direction of the grain is increased by 30%

Quick mass production:

Make acrylic templates (repeatable rubbing)

Purchase pre-indented cardboard (save 80% of labor hours)

Table of Contents

Latest Products

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi