Unfolding Magnetic Box

Material: 2.5 mm- 3 mm thick premium paperboard

Magnet Strength: 10N-15N holding force

Printing Options: CMYK, Pantone, spot UV, foil stamping

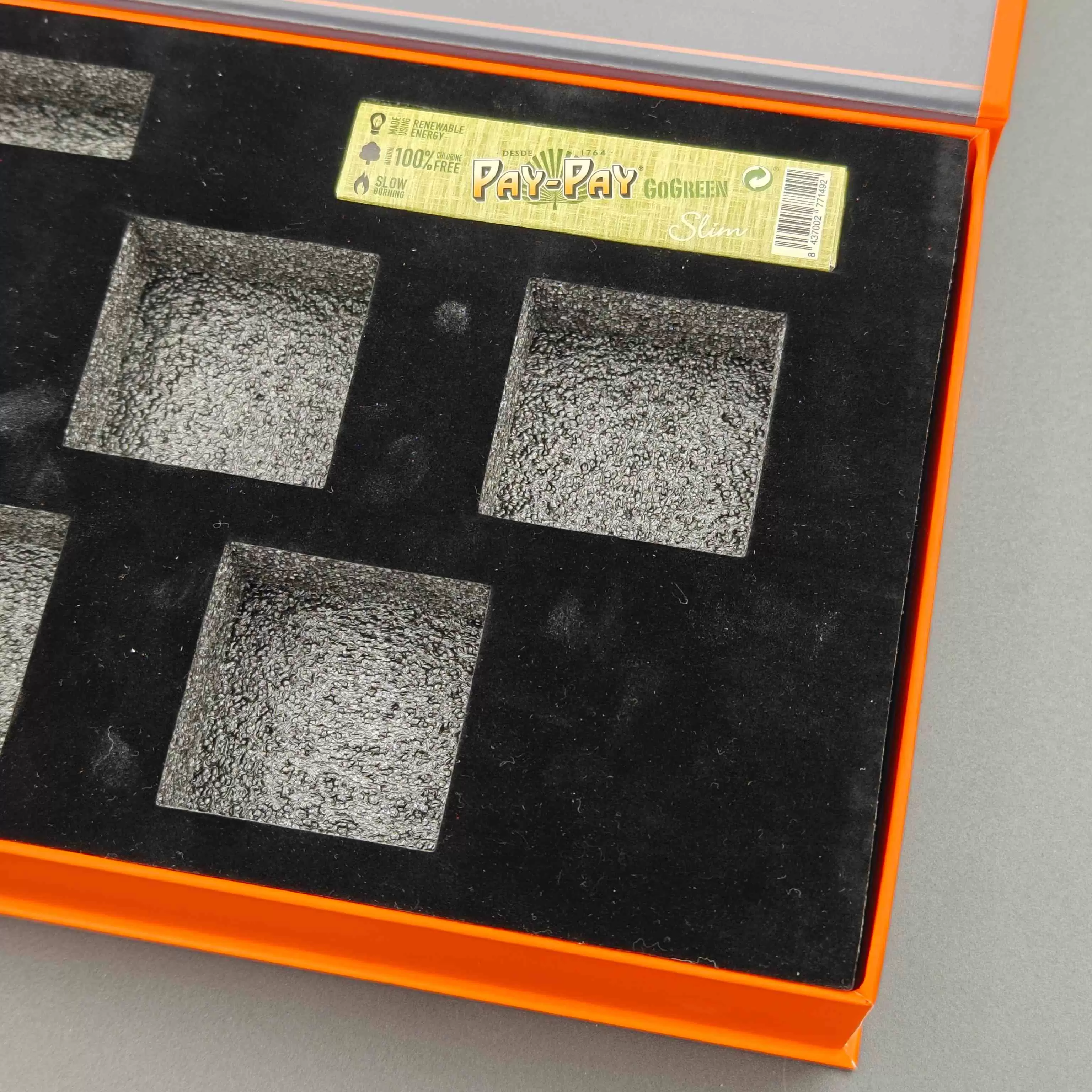

Interior: Custom foam, velvet, or satin linings

Fully Customizable: Choose from sizes, colors, and premium finishes

Durable & Functional: Sturdy construction with a polished, retail-ready look.

Fast Turnaround: Samples available in 5-7 days.

MOQ: 500

Key Features:

● Sleek Magnetic Closure

● Luxury Gold Hot Stamping

● Elegant Embossing

● Book-Style Unfolding

● Eco-Friendly Materials

Elevate your brand with our unfolding magnetic box, a luxurious packaging solution that combines innovative design with exquisite craftsmanship. Featuring gold hot stamping and embossing detailing textures, this premium packaging delivers an unforgettable unboxing experience.

Key Features of Unfolding Magnetic Box:

● Sleek Magnetic Closure—Smooth-opening design with strong neodymium magnets for secure sealing.

● Luxury Gold Hot Stamping—Custom metallic foil branding for a premium finish.

● Elegant Embossing—Deeply debossed textures for enhanced tactile appeal.

● Book-Style Unfolding—Opens like a refined journal for dramatic presentation.

● Eco-Friendly Materials—FSC-certified rigid paperboard with recyclable options.

Why Choose Our Book-Shape Box?

Redefine luxury unboxing with our unfolding magnetic box, a masterpiece of functional design that blends cutting-edge engineering with artisanal craftsmanship. These cardboard boxes feature:

Craftsmanship Highlights:

▸ Precision Gold Hot Stamping 0.1mm tolerance metallic detailing

▸ Artisan Embossing - Deep 3D textures with 0.3mm relief depth

▸ Dual-Finish Surfaces - Combine matte and gloss effects in a single construction

▸Military-Grade 15N force neodymium cores ensure a silent, seamless closure

Advantage

● Fully Customizable: Choose from sizes, colors, and premium finishes

● Durable & Functional: Sturdy construction with a polished, retail-ready look.

● Fast Turnaround: Samples available in 3-5 days, production in 10-15 days.

● German Heidelberg UV Printing Equipment.

● Over 30 years of experience in one-stop packaging and printing factories.

● FSC environmental certification.

● Perfect for High-End Brands: Ideal for jewelry, watches, cosmetics & luxury gifts.

Technical Specifications:

Material: 2.5 mm- 3 mm thick premium paperboard

Magnet Strength: 10N-15N holding force

Printing Options: CMYK, Pantone, spot UV, foil stamping

Interior: Custom foam, velvet, EVA, or satin linings

— Customize the Steps to Unfold the Magnetic Box

Customizing an expandable magnetic box requires a comprehensive approach, including product requirements, design planning, and collaboration with the manufacturer. The following process is a clear step-by-step guide to ensure the final product meets your expectations:

Step 1: Clarify Requirements and Basic Positioning

This is the core prerequisite for customization. It's crucial to clearly define "what the box will contain and what effect it will achieve" to avoid repeated revisions later.

1. Determine the item information:

Clarify the item's dimensions (length, width, and height), weight, and shape (e.g., whether it is fragile or has sharp edges; for example, jewelry requires scratch protection, and electronics require buffer space).

If multiple items need to be stored simultaneously, determine how the items will be arranged (whether they are layered or require fixed positions). This will help you determine the box's internal structure (e.g., whether lining or partitions are required).

2. Define the intended use and style:

Purpose: Is it for gift packaging (emphasizing aesthetics and a sense of ceremony), retail packaging (emphasizing brand recognition), or storage (emphasizing durability)? Style: Determine the style based on the brand's tone or usage scenario (e.g., for a light luxury style, choose hot stamping with dark specialty paper; for a simple style, choose plain kraft paper; for a holiday theme, choose corresponding pattern elements).

3. Determine the budget and order level:

Clarify the order quantity (small batch trial production or large-scale production; small batches may not be suitable for complex hot stamping processes).

Set a rough budget range to facilitate the selection of materials and processes when communicating with us (e.g., if the budget is limited, prioritize basic cardboard with monochrome printing; if the budget is sufficient, upgrade to specialty paper with 3D embossing).

Step 2: Design Plan (Structure + Appearance)

Refine the design based on the requirements, including the box's unfolded structure, materials, and decorative techniques.

1. Determine the unfolding structure and style:

The core of an "expandable magnetic box" is its expandability (for easy storage and transport) and magnetic closure. Therefore, the basic structure must be determined first.

Common unfolding styles include "clamshell" (the lid and body are connected by a folded edge, resulting in a flat surface when unfolded) and "folding and splicing" (the body is composed of multiple cardboard pieces held together by magnetic attraction or tabs, allowing for detachable and stackable storage when unfolded). Prioritize structures that take up minimal space when unfolded and are easy to assemble (to reduce storage and shipping costs).

Magnetic Position Design: Determine the magnet's placement (e.g., along the edge of the lid or on the body) to ensure a secure closure. (The magnet's strength should match the size of the box to avoid being too weak for easy opening or too strong for difficult opening.)

2. Material Selection:

Base Material

Cardboard (such as gray cardboard, with a thickness of 1.5-3 mm, depending on the size and load capacity of the box; larger and heavier boxes require thicker cardboard) is preferred to ensure structural strength when unfolded and folded.

Surface Material

Choose based on style (such as specialty paper (for a strong texture), coated paper (suitable for high-definition printing), or kraft paper (for eco-friendliness and simplicity)). If waterproofing is required, matte or glossy laminates are available.

Inner Lining Material

If protection is required, EVA foam (scratch-resistant), flocking (for a high-end feel), or paper dividers (for a low-cost option) are available.

3. Exterior Design:

Printing Content: Determine whether to include a brand logo, pattern, or text (such as product descriptions or greetings), and specify the placement and size of the pattern.

Process Selection: Choose a process based on budget and style.

Basic Processes: Single-color printing, four-color printing (suitable for complex patterns), lamination (for stain resistance);

Advanced Processes: Gold/silver hot stamping (for a metallic texture, highlighting the logo), UV varnish (for a glossy finish, creating a layered effect), embossing/debossing (for a three-dimensional texture and a pleasant touch), and hollowing (for a more design-oriented feel).

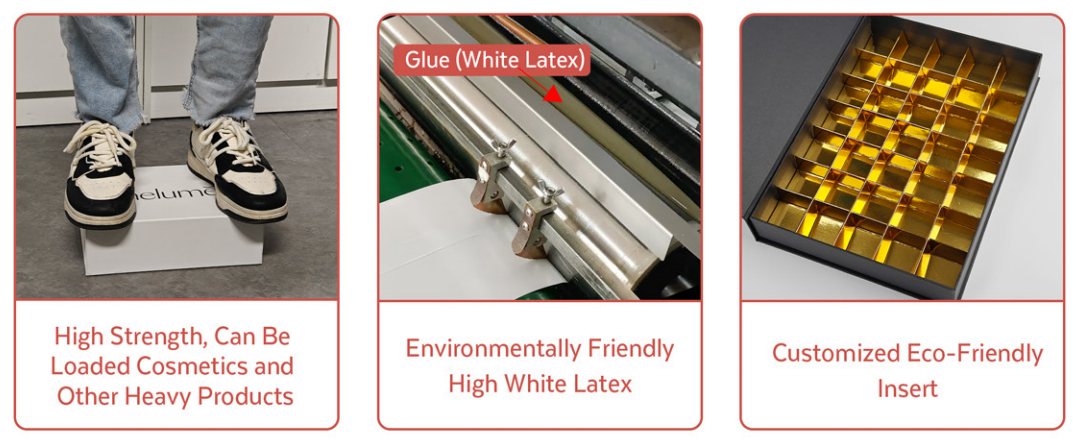

High-quality Magnetic Closure Box Test

Our magnetic closure boxes are high-strength and can be loaded with cosmetics and other heavy products.

Step 3: Proofing and Confirmation (Critical Step):

Proofing is essential before mass production to ensure that the product meets expectations and avoids errors during production.

1. Pay the Proofing Fee and Wait for Samples:

Pay the proofing fee and confirm the proofing lead time (usually 5-7 days, longer for complex processes).

2. Detailed Sample Inspection:

Structure: Whether it unfolds smoothly, whether it is secure after folding (not loose), whether the magnetic closure is secure (whether it clicks when opened and closed, and whether the lid falls off when inverted);

Dimensions: Measure the length, width, and height of the box to see if it can fit the item (whether the reserved space is appropriate and whether the lining fits the item).

Appearance: Whether the printing is clear (no blurring or color misregistration), whether the workmanship is up to standard (e.g., whether the hot stamping is even and whether the embossing is clear), whether the material is consistent with the agreement (whether there are any surface defects and whether the lining is flat);

Details: Whether the edges are smooth (no burrs to avoid scratches) and whether there are any creases or breakage risks at the folds.

3. Submit Revisions and Re-sample:

If you encounter any issues, please promptly provide feedback and clearly identify the revisions (e.g., "replace with a stronger magnet" or "adjust the logo printing color"). Our factory will resample until the sample fully meets your requirements. (We recommend retaining a qualified sample as an acceptance standard for mass production.)

Step 4: Order Confirmation and Mass Production

Once the sample is confirmed, you can place a formal order and pay (typically 30%-50% prepayment, with the balance due before shipment). Our customer service staff will closely monitor production progress and provide timely feedback to ensure timely delivery.

Our Professional Design Service Team is at Your Service

-

Wechat

+8613616008761

Wechat

+8613616008761 -

Email

Email

-

Tel

+86-136-1600-8761

Tel

+86-136-1600-8761

en

en es

es ru

ru fr

fr de

de it

it ja

ja ar

ar pt

pt ko

ko tr

tr nl

nl fi

fi